The circular economy is reshaping how businesses manage resources, moving away from wasteful practices toward reusing, recycling, and repurposing materials. For companies, this shift isn't just about reducing waste - it’s also about cutting costs, creating new revenue streams, and meeting sustainability goals. Collaboration is key, and businesses are forming partnerships to overcome challenges like high costs, limited infrastructure, and complex regulations.

Here are five collaboration models that businesses can use to turn surplus inventory and waste into opportunities:

- Shared B2B Marketplaces: Online platforms like ForthClear connect businesses to buy and sell surplus inventory, reducing waste and creating revenue.

- Reverse Logistics Partnerships: Collaborations focused on collecting, refurbishing, or recycling returned or end-of-life products.

- Product Life Extension: Partnerships that repair, refurbish, or resell products to extend their lifespan and reduce waste.

- Resource Recovery & Industrial Symbiosis: One company’s waste becomes another’s input, creating closed-loop systems and reducing raw material costs.

- Product-Service Systems: Models like leasing or subscriptions that keep businesses accountable for product lifecycles, encouraging reuse and recycling.

These models don’t just help the planet - they also streamline operations, save money, and scale for businesses of all sizes. Whether you're offloading surplus inventory or building long-term partnerships, these approaches offer practical ways to embrace circular practices and create lasting value.

Advancing the Circular Economy: Collaborative Efforts to Deliver Value

1. Shared B2B Marketplaces for Surplus Inventory

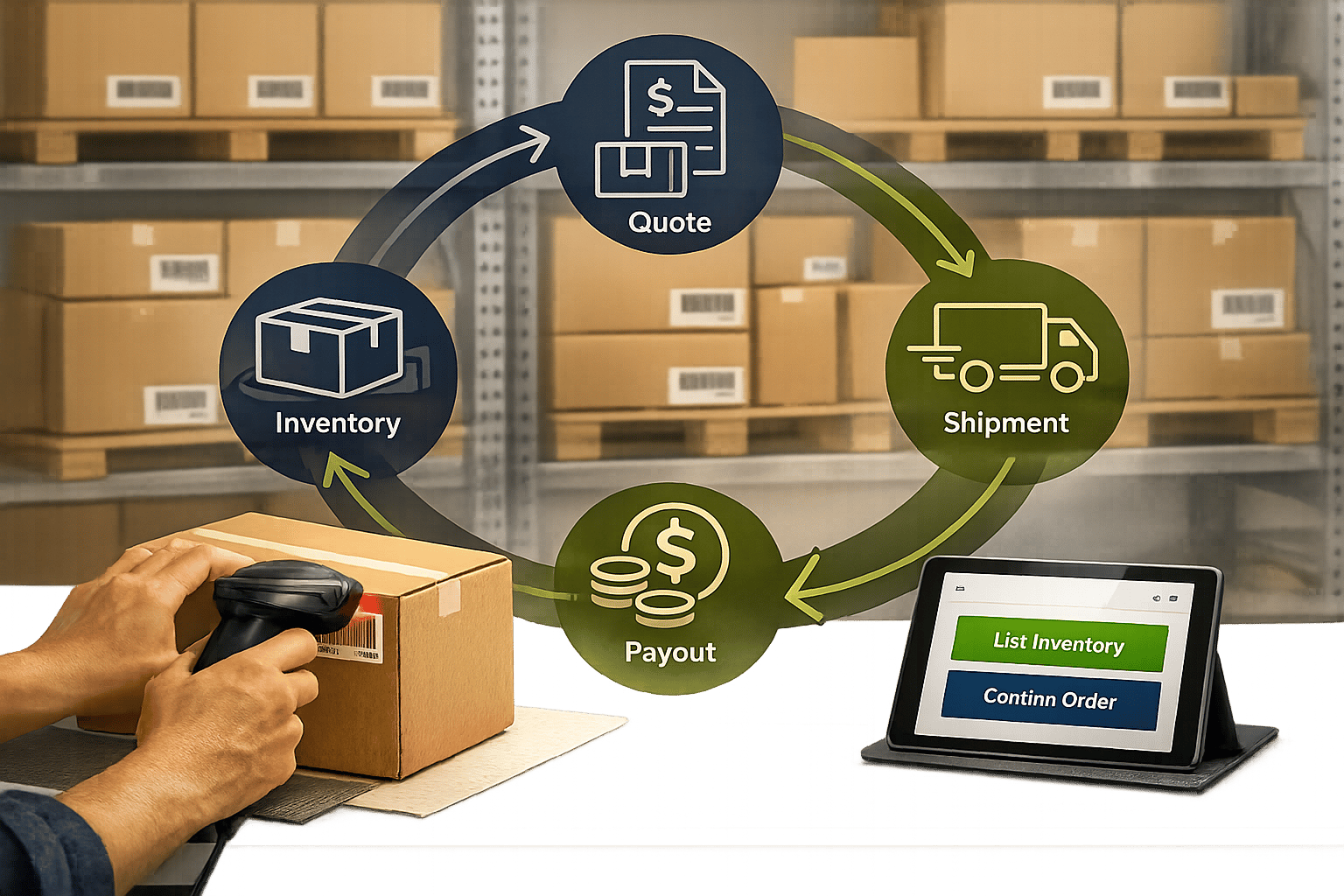

Shared B2B marketplaces are a practical starting point for businesses looking to embrace circular economy principles. These online platforms connect companies with surplus inventory to buyers searching for affordable materials, ensuring resources remain in use rather than going to waste.

Here’s how it works: businesses post their excess stock - whether it’s overstock, slow-moving items, or products nearing expiration - on a centralized platform. Buyers can then browse and purchase what they need. A great example is ForthClear, a U.S.-based marketplace offering a secure space for trading surplus goods across categories like electronics, apparel, and home goods.

"Easy to get started and offload some of our products that were nearing expiry date. Very helpful that ForthClear helps to find buyers in the process."

– Hylke Reitsma, Co-founder

Environmental Impact

These marketplaces offer more than just convenience - they’re also a win for the environment. By redirecting surplus inventory from landfills back into use, they help reduce waste and curb the need for new raw materials. Choosing surplus items over newly produced ones also cuts down on Scope 3 emissions tied to manufacturing and transportation, aligning with sustainability goals.

Streamlining Operations

Managing surplus inventory can be a headache, but digital marketplaces simplify the process. Features like bulk CSV uploads, integrated order tracking, and direct messaging replace tedious disposal procedures with efficient, user-friendly tools. This means businesses can quickly list items, connect with buyers, and oversee transactions with minimal hassle. As Gordon Belch, Co-founder, notes:

"ForthClear has revolutionized how we handle excess inventory. The secure payment system and quality suppliers have made our sourcing process incredibly efficient."

For buyers, these platforms provide real-time access to surplus stock from various suppliers, speeding up procurement and saving time on sourcing materials.

Financial Benefits

Shared marketplaces also make financial sense. Sellers can turn surplus inventory into revenue instead of writing it off as a loss, while also freeing up warehouse space and cutting storage costs. Buyers, on the other hand, gain access to materials at steep discounts - ForthClear, for instance, offers savings of up to 70% off retail prices - all while simplifying their procurement process.

Scalability for Growth

One of the standout features of shared B2B marketplaces is their scalability. Businesses of all sizes can join and connect with extensive networks of trading partners. This flexibility not only maximizes the value of surplus inventory but also lays the groundwork for more collaborative initiatives, such as reverse logistics.

2. Reverse Logistics Partnerships

Reverse logistics partnerships take collaboration in the circular economy to the next level by concentrating on what happens after products reach the customer. These partnerships bring businesses together to manage the collection, processing, and repurposing of returned items, end-of-life products, or materials that might otherwise be discarded. Unlike traditional logistics, which focuses on moving products to customers, reverse logistics aims to recover value through refurbishment, recycling, or resale. This approach lays the groundwork for further initiatives that maximize resource efficiency.

Environmental Impact

These partnerships play a key role in reducing waste and conserving resources. Take H&M's collaboration with I:CO, for instance. In just one year, they collected 29,005 tons of textiles for reuse and recycling, sorting them into categories like rewear, repurposing for other uses, or recycling into new fibers. Similarly, programs like those run by TerraCycle, in partnership with major brands such as P&G, Unilever, and Nestlé, tackle the challenge of recycling materials that are often difficult to process through traditional systems.

Operational Efficiency

By pooling resources and leveraging digital platforms, reverse logistics partnerships streamline operations. Real-time data sharing helps partners reduce bottlenecks and make smarter, more efficient decisions about managing returned goods.

Cost Savings

Efficiency improvements translate directly into cost reductions. Shared expenses for transportation, warehousing, and processing make reverse logistics more affordable. For example, Re-Tek collects and resells redundant IT equipment, sharing revenue with the original owners. This turns what would have been a disposal expense into a profit opportunity. Even items unsuitable for resale can be broken down for spare parts or recycled, ensuring that no value goes to waste. Platforms like ForthClear also help by connecting sellers with buyers for discounted surplus inventory, reducing financial losses.

Scalability for Businesses

Reverse logistics partnerships are adaptable for businesses of all sizes and across industries. Shared recycling programs or return centers allow smaller companies to benefit from circular economy practices without needing significant upfront investment. Re-Tek’s expansion from the UK to partnerships across Europe highlights how these models can grow while maintaining efficiency and value recovery. Digital platforms further enhance scalability by enabling seamless coordination and data sharing among partners, letting businesses focus on their core operations while advancing sustainability efforts. These partnerships also complement other collaborative models, creating a stronger, more integrated approach to the circular economy.

3. Product Life Extension Collaborations

Product life extension collaborations are partnerships where businesses work together to repair, refurbish, and extend the lifespan of products and components. Instead of focusing solely on selling new items, these efforts prioritize keeping existing products in use for as long as possible. This approach not only helps conserve resources but also significantly reduces waste and environmental harm.

Environmental Impact

One of the standout benefits of these collaborations is their ability to cut down on waste and reduce greenhouse gas emissions. Take Patagonia's Worn Wear program, for example. In 2024, it repaired over 130,000 clothing items, ensuring they stayed out of landfills. The program goes beyond repairs by offering buy-back and resale options for used items, as well as recycling for products that are beyond repair.

In the electronics industry, similar initiatives are making a difference. Refurbishment partnerships are helping divert outdated devices from landfills, showcasing the broader environmental impact of these efforts.

Operational Efficiency

Extending the life of products doesn’t just benefit the planet - it also boosts operational efficiency. By sharing resources, expertise, and infrastructure, businesses can streamline repair and refurbishment processes. A great example is Philips Refurbished Systems. Through its trade-in program, hospitals can exchange old medical equipment for discounts on new systems. Philips then refurbishes the traded equipment and resells it, creating a smooth, efficient cycle that benefits everyone involved.

Collaborations like these also reduce redundant efforts through shared service centers and joint ventures. Digital tools enhance the process further by enabling real-time tracking of product usage, maintenance schedules, and end-of-life recovery. These platforms also improve knowledge sharing and standardization across partner networks, ensuring smoother operations.

Cost Savings

Extending product lifecycles can lead to considerable cost savings. Businesses cut down on procurement costs for new materials, save on waste disposal fees, and share refurbishment infrastructure costs with partners. By delaying the need for new equipment and benefiting from economies of scale in repair and remanufacturing, companies can turn what would have been disposal costs into profitable opportunities through revenue-sharing models.

Scalability for Businesses

These collaborations work for businesses of all sizes and across various industries. Smaller companies can tap into larger networks to access refurbishment facilities and expertise without needing significant upfront investments. Digital platforms also make it easier to coordinate and share data between partners.

A notable example comes from the automotive industry, where Peugeot, Citroën, and Toyota joined forces to develop small city cars in a shared factory. This collaboration reduced initial investment costs and extended vehicle lifecycles through upgrades and refurbishments. Additionally, digital marketplaces are helping businesses from different sectors connect, enabling the reuse and refurbishment of surplus inventory.

sbb-itb-bc600a0

4. Resource Recovery and Industrial Symbiosis

Resource recovery and industrial symbiosis bring a fresh perspective to business-to-business (B2B) collaborations. In this model, one company's waste becomes another's valuable resource, creating efficient, closed-loop systems. By sharing resources, businesses turn what was once waste into profitable inputs, reducing waste and generating new revenue opportunities.

This concept thrives on strategic partnerships where companies exchange waste streams, surplus materials, or byproducts. For instance, a ceramics manufacturer might supply broken pieces to a brick maker, converting waste into a useful material. These partnerships create opportunities to transform waste into income, benefiting both parties.

Environmental Impact

The environmental benefits of resource recovery and industrial symbiosis are clear and measurable. A prime example is the Kalundborg Symbiosis in Denmark. Since the 1970s, this collaboration among eight private and public partners - including Novo Nordisk, DONG Energy, and the local municipality - has achieved remarkable results. By 2023, their efforts reduced CO₂ emissions by an impressive 635,000 tons annually.

These systems help keep materials in circulation, reducing landfill waste and the need for virgin raw materials. By conserving natural resources and minimizing the environmental toll of material extraction and processing, they contribute directly to sustainability goals. Businesses also benefit from lower Scope 3 emissions, thanks to smarter resource use.

Operational Efficiency

Resource sharing doesn’t just help the environment - it also streamlines business operations. By creating predictable material flows, companies can simplify their supply chains, reduce logistical headaches, and cut transportation costs. Shorter delivery times and improved supply chain resilience are added bonuses.

On top of that, shared resources and infrastructure often lead to more efficient production processes. Coordinating waste streams and material needs can improve capacity utilization and reduce downtime. Digital platforms play a growing role in these efforts, offering tools for resource tracking, inventory management, and seamless exchanges between partners.

Cost Savings

The financial upside of resource recovery is hard to ignore. The Kalundborg Symbiosis, for instance, saves about $24 million annually through resource-sharing initiatives. These savings come from lower waste disposal costs, reduced raw material expenses, and shared infrastructure investments.

Many companies discover that their waste streams can generate revenue. Instead of paying for disposal, businesses can sell their byproducts, turning a cost into profit. These resource recovery models also pave the way for broader collaboration in circular supply chains.

Scalability for Businesses

Resource sharing works for businesses of all sizes, though the approach may differ based on scale and industry. Larger manufacturers often establish formal partnerships within industrial parks or regions. Meanwhile, smaller companies can leverage digital B2B marketplaces to trade surplus materials and byproducts.

Platforms like ForthClear make it easier for businesses to participate in resource recovery. These platforms allow companies to buy and sell surplus inventory across various categories, with features like secure escrow payments, verified suppliers, and real-time communication. This makes resource sharing accessible even for businesses without the capacity to form direct partnerships. Public-private initiatives like NextCycle Washington also play a role by facilitating collaborations that address municipal waste streams while offering financial and technical support.

Scaling these models successfully requires identifying the right partners, supportive policies, and neutral organizations - such as trade associations or public agencies - that can coordinate efforts and lower barriers for small businesses.

5. Product-Service Systems and Circular Supply Agreements

Product-service systems (PSS) and circular supply agreements mark a shift in how businesses and consumers interact with products. Instead of selling products outright, companies now offer access through leasing, subscriptions, or pay-per-use arrangements. This approach keeps businesses accountable for their products throughout their lifecycle, encouraging durability, repairability, and resource recovery. By aligning business goals with sustainable practices, these models complement other collaborative efforts to promote responsible resource use.

In PSS, the manufacturer or service provider retains ownership of the product, while customers pay based on usage or performance. Circular supply agreements take this concept further by setting up long-term contracts that ensure products and materials re-enter the supply chain through refurbishment, remanufacturing, or recycling. This creates a win-win scenario: businesses benefit from maintaining products longer, while environmental goals are met by reducing waste and conserving resources.

Environmental Impact

These service-oriented models have a clear environmental upside. When companies maintain ownership, they prioritize designing products that last longer and are easier to repair, moving away from planned obsolescence. This reduces the need for resource extraction, cuts emissions during manufacturing, and minimizes waste.

Take Patagonia, for example. Its programs demonstrate how extending product lifespans can significantly cut waste and emissions. Similarly, IT asset management initiatives show that keeping products in use longer leads to lower Scope 3 emissions through more efficient resource use. These environmental benefits go hand-in-hand with the streamlined operations made possible by integrated service models.

Operational Efficiency

Beyond environmental benefits, PSS also boosts operational performance. Centralized asset management systems allow service providers to monitor product performance, predict maintenance needs, and prevent breakdowns. By leveraging technology, companies can ensure products perform optimally while avoiding costly repairs and downtime.

Philips Refurbished Systems is a great example. The company lets hospitals trade in old medical equipment for discounts on new systems. Philips then refurbishes and resells the equipment, offering hospitals an affordable way to upgrade while cutting waste. This model not only extends product life but also helps Philips reach new customer segments.

Digital tools take these efficiencies even further. Cloud-based platforms and automated billing systems make it easier for businesses - large and small - to manage services. Real-time tracking of product usage, maintenance schedules, and performance metrics across locations simplifies operations and reduces complexity.

Cost Savings

PSS offers financial benefits by lowering upfront costs and providing predictable expenses. Instead of making large purchases, businesses pay for what they use, improving cash flow and lowering financial risks. Maintenance, repairs, and upgrades are typically included in the agreement, eliminating unexpected costs.

Circular supply agreements add another layer of savings. Long-term contracts often lock in pricing and reduce supply chain disruptions. By refurbishing or upgrading assets as part of the service, companies avoid obsolescence costs. For example, H&M’s partnership with I:CO has collected 29,005 metric tonnes (about 32,000 short tons) of textiles for reuse and recycling. This program generates revenue from repurposed materials while cutting textile waste.

These models also help businesses avoid disposal fees and even create new revenue streams by recovering valuable materials.

Scalability for Businesses

One of the strengths of these models is their scalability across industries. With the help of digital platforms and standardized contracts, businesses of all sizes can participate without needing massive infrastructure investments. Industry consortia and third-party platforms simplify the process, making it easier for smaller companies to join.

Platforms like ForthClear are leading the way. They enable businesses to securely buy and sell surplus inventory, offering features like escrow payments, verified suppliers, bulk pricing, and real-time communication. These tools make it easier to manage surplus assets and implement circular agreements without building complex logistics systems from scratch.

This scalability applies to industries ranging from manufacturing and electronics to textiles and medical equipment. Success hinges on finding the right partners, setting clear performance goals, and using technology to track and coordinate activities. As more businesses adopt these models, network effects amplify the benefits, creating better matches between supply and demand and increasing material flows.

The success of these service models also strengthens customer relationships. For instance, Patagonia found that 95% of Worn Wear customers reported increased brand loyalty due to the program. This demonstrates how circular service models not only support environmental goals but also build stronger connections with customers, laying the groundwork for sustainable business growth.

Comparison Table

The table below outlines various collaboration models used in circular economy practices across the U.S., focusing on their performance in areas like waste reduction, efficiency, cost savings, and scalability. This breakdown can help you identify the most suitable approach for your business needs.

| Collaboration Model | Waste Reduction Impact | Efficiency Gains | Cost Savings | Business Scalability |

|---|---|---|---|---|

| Shared B2B Marketplaces for Surplus Inventory | High – Resale prevents products from ending up in landfills | High – Real-time trading minimizes inventory holding costs and speeds up turnover | Moderate to High – Companies can recover 10–30% of the original product value | High – Digital platforms support rapid expansion across multiple categories |

| Reverse Logistics Partnerships | High – Example: Re-Tek diverts 99% of electronic products from landfills through refurbishment | Moderate – Simplifies returns processing but requires complex coordination | High – Asset recovery can save large manufacturers hundreds of thousands annually | Moderate to High – Relies on robust logistics systems for scaling |

| Product Life Extension Collaborations | High – Example: Patagonia repaired over 130,000 items in 2024, extending their use | Moderate – Reduces the need for replacements but depends on well-coordinated maintenance services | Moderate – Maintenance partnerships lower replacement costs by 20–40% | Moderate – Growth is limited by the availability of service networks and technical expertise |

| Resource Recovery and Industrial Symbiosis | Very High – Example: Kalundborg’s 50+ exchanges maximize resource use across partners | High – Shared resources reduce raw material processing and waste disposal | High – Projects often report millions in annual savings | Moderate – Requires geographic proximity and compatible industries |

| Product-Service Systems and Circular Supply Agreements | Moderate to High – Example: H&M and I:CO collected 29,005 tons of textiles through service-based programs | High – Service models enhance asset utilization and enable predictive maintenance | Moderate – Customers see 15–25% reductions in total cost of ownership | High – Recurring revenue models scale well across diverse markets |

The data highlights how each model delivers different benefits, making it easier to align strategies with specific business goals. For instance, shared B2B marketplaces, like platforms such as ForthClear, provide a quick and efficient way to trade surplus inventory. This approach is particularly effective for businesses looking for immediate results.

Electronics companies often see the greatest impact from reverse logistics, while apparel brands benefit significantly from product life extension collaborations. For businesses new to circular practices, starting with shared B2B marketplaces can yield fast returns. Over time, scaling into areas like reverse logistics or resource recovery can align with specific product types and regional opportunities, helping to build sustainable and scalable circular economy practices.

Conclusion

Shifting to circular economy practices in the B2B world requires more than isolated efforts - it thrives on partnerships that amplify impact. A great example of this is the NextCycle Washington initiative, which, in its first year, supported over 50 organizations in launching circular business models by pooling resources and fostering strategic collaborations.

Digital platforms are also playing a transformative role. Take ForthClear, for instance. With features like secure escrow services, verified suppliers, and real-time communication, it’s reshaping surplus trading across the U.S. The results speak for themselves: a 95% satisfaction rate and a streamlined approach to circular commerce.

"ForthClear has revolutionized how we handle excess inventory. The secure payment system and quality suppliers have made our sourcing process incredibly efficient", says Gordon Belch, Co-founder.

These tech-driven solutions aren’t just about convenience - they deliver measurable economic benefits. By tapping into shared marketplaces and reverse logistics, businesses can turn surplus inventory into value, cutting waste and improving resource efficiency. The result? A win for both the bottom line and the environment.

For companies looking to take their first step into the circular economy, shared B2B marketplaces offer a practical starting point. Immediate savings, reduced waste, and new revenue streams make this an attractive entry point. As companies gain experience, they can explore more advanced strategies like industrial symbiosis or product-service systems to deepen their commitment.

FAQs

How do shared B2B marketplaces like ForthClear help businesses reduce waste and meet sustainability goals in a circular economy?

Shared B2B marketplaces, such as ForthClear, are pivotal in advancing the circular economy. They allow businesses to trade surplus inventory, cutting down on waste, giving products a longer life, and encouraging more eco-friendly business practices.

ForthClear offers a range of tools to streamline this process, including secure escrow payments, verified supplier networks, bulk pricing options, real-time communication features, and order tracking capabilities. These features not only simplify surplus stock management but also help businesses align with their sustainability objectives.

What are the benefits of reverse logistics partnerships for businesses, and how do they improve efficiency and reduce costs?

Reverse logistics partnerships bring a host of advantages to businesses. By simplifying the process of handling returns, refurbishing items, or recycling products, companies can cut down on waste, reclaim value from unsold inventory, and lessen their environmental footprint. These partnerships also help businesses save on operational costs by streamlining transportation, storage, and inventory management.

On top of that, reverse logistics can boost customer satisfaction by offering hassle-free return and recycling options. Over time, these improvements can strengthen brand loyalty and support a more sustainable approach to business.

How do product-service systems help businesses grow and build stronger customer relationships in a circular economy?

Product-service systems (PSS) help businesses grow by moving away from just selling physical products and instead offering a mix of products and services as complete solutions. This model opens the door to steady revenue streams, better use of resources, and less waste - key principles of a circular economy.

By focusing on services such as maintenance, upgrades, or leasing, PSS encourages stronger connections with customers through continuous interaction and customized offerings. This approach not only boosts customer satisfaction but also strengthens loyalty, as businesses collaborate with customers to meet their needs while supporting more sustainable practices.