Excess inventory can drain your cash flow and hinder growth. Here’s how to sell it quickly and efficiently:

- Review Inventory: Identify slow-moving or non-selling items using inventory management tools.

- Discounts & Promotions: Use bulk discounts, flash sales, or bundle deals to clear stock.

- B2B Marketplaces: Leverage platforms like ForthClear to connect with buyers and streamline bulk sales.

- Professional Liquidators: Partner with experts to move large quantities fast, though at lower returns.

- Expand Sales Channels: Explore new markets, resale networks, or international buyers for surplus goods.

- Online Auctions: Use competitive bidding platforms to sell quickly, often at better prices.

- Improve Inventory Management: Adopt demand forecasting, automated alerts, and regular clearance cycles to prevent future overstock.

Act now to turn your surplus stock into cash and free up resources for growth.

Unload Inventory Fast! Bulk Selling Secrets You NEED To Know!

1. Review Your Inventory to Find What Needs to Go

The first step to turning excess stock into cash is taking a hard look at your inventory. By identifying what’s not selling, you can make informed decisions about how to free up space and recover costs. This process starts with analyzing your stock and understanding the financial impact of items that just aren’t moving.

Spot Slow-Moving and Outdated Items

Your inventory management system is your best friend here. Use it to track metrics like inventory turnover ratios and the average number of days it takes to sell each product. These numbers will quickly show you which items are flying off the shelves and which are gathering dust. A simple FSN (Fast, Slow, Non-moving) analysis can help you categorize your inventory:

- Fast-Moving Inventory: Items that sell quickly, often within weeks.

- Slow-Moving Inventory: Products that take months to sell.

- Non-Moving Inventory: Stock that hasn’t sold in six months or more.

For industries like fashion, anything unsold after 90 days is typically considered slow-moving. To dig deeper, calculate the consumption rate - how many units sell over a specific time period. Items with consistently low sales should be flagged for action. Many inventory management tools can automate this process, even alerting you when products reach critical thresholds.

| Category | Description |

|---|---|

| Fast-Moving Inventory | Items sold or used quickly within a short timeframe |

| Slow-Moving Inventory | Products that take longer to sell or use |

| Non-Moving Inventory | Items unsold or unused for extended periods |

Understand Storage and Holding Costs

To get a clear picture of how much excess inventory is costing you, calculate your holding costs. These expenses usually account for 20% to 30% of your total inventory value. Breaking down holding costs into four categories can help:

- Capital Costs: Money tied up in unsold inventory, including financing expenses.

- Storage Costs: Warehouse rent, utilities, insurance, and property taxes.

- Service Costs: Labor, equipment upkeep, and IT system expenses.

- Risk Costs: Losses from obsolescence, damage, theft, or depreciation.

For example, TechCraft Innovations calculated their holding costs by dividing their total inventory expenses ($76,500) by the inventory value ($350,000), arriving at a 21.86% cost rate. Regularly tracking these costs can reveal trends and highlight which items are draining resources. Focus on liquidating products where holding costs outweigh their sales potential.

Prioritize Items for Liquidation

Once you understand your costs, it’s time to rank your inventory based on how urgently it needs to go. Start by organizing stock into time-in-stock tiers, like items held for 30 days, 60 days, and 90+ days. This gives you a clearer picture of what’s been sitting too long.

Key factors to consider when prioritizing inventory include age, condition, and seasonal demand. Older items are often harder to sell and more likely to lose value. Seasonal goods that won’t sell until next year should also be high on your list. To test demand, try running small promotions or flash sales to gauge customer interest.

Set markdowns based on how long items have been in stock:

- 10% for stock held 30 days

- 25% for 60 days

- 50% for 90+ days

Look at past sales data, original pricing, and previous discount levels to determine realistic liquidation values. Items with poor performance or high depreciation - like perishable goods or outdated tech - should be prioritized for quick sale.

2. Use Discounts and Promotions to Move Stock

Discounts and promotions can be a powerful way to turn excess inventory into cash while pulling in budget-conscious buyers. The trick is striking the right balance - clearing stock quickly without sacrificing too much on profit margins.

Set Up Bulk Discount Pricing

Offering volume-based discounts is a smart way to encourage larger orders, especially for B2B customers who often buy in bulk. This strategy rewards customers with better per-unit prices when they purchase more, motivating them to increase their order size.

For example, you can use tiered pricing to offer progressively larger discounts as the order size grows. Here's how it might look:

| Tier | Purchase Volume | Percentage Discount | Price Example (Based on $20 Business Price) |

|---|---|---|---|

| 1 | 5 to 9 units | 5% off | $19.00 per unit |

| 2 | 10 to 24 units | 10% off | $18.00 per unit |

| 3 | 25 to 49 units | 15% off | $17.00 per unit |

| 4 | 50 to 99 units | 20% off | $16.00 per unit |

| 5 | 100+ units | 25% off | $15.00 per unit |

Research shows that bulk pricing can increase sales volume by up to 20% and boost the number of units sold by 25%. B2B buyers, in particular, benefit from this approach - they tend to purchase 74% more units per order and return 42% fewer items compared to B2C buyers.

To make bulk pricing work, analyze your customer data to identify your big spenders and their common purchasing patterns. Make sure the discounts are enticing enough to drive action - 82% of B2B buyers actively look for opportunities to negotiate prices.

Run Time-Limited Sales

Flash sales are another effective way to create urgency and move excess inventory fast. When buyers know a deal is only available for a short time, they’re more likely to act quickly instead of hesitating. This sense of urgency is especially useful for clearing out slow-moving products.

For example, you could offer steeper discounts on items that have been sitting in storage the longest. Adjust the discount percentage and sale duration based on how much inventory you need to clear. Adding countdown timers or "limited time only" messaging can amplify the urgency, prompting faster decisions - particularly in B2B settings where internal approvals can sometimes delay purchases.

Keep in mind that only 4% of closeout teams recover more than 75% of costs on discounted stock. Considering the 20–30% carrying costs of holding onto inventory, it often makes financial sense to sell items quickly, even at a reduced margin.

Bundle Excess Items with Popular Products

Bundling is a clever way to move slow-moving inventory without heavily discounting it. By pairing excess stock with best-selling items, you can increase perceived value while boosting the overall order size.

For example, if you have extra office supplies, bundle them with high-demand items like printers or laptops. Seasonal items that didn’t sell as expected can also be combined with year-round products that customers regularly buy. One successful case involved a beauty brand in KSA, which used its inventory system to identify slow-moving items and bundled them with popular products, offloading three months’ worth of stock to salon distributors.

When pricing bundles, make sure the combined cost is lower than if the items were sold separately, but still allows for a reasonable profit margin. A "buy two, get one free" offer is one way to do this, where the free item comes from your excess inventory. Alternatively, create themed bundles with a slight discount compared to individual prices. Experiment with different combinations to find what resonates with your customers and clears out your stock most effectively.

Using these strategies not only clears out surplus inventory but also frees up cash that you can reinvest in growing your business.

3. Use B2B Marketplace Platforms

B2B marketplace platforms are a direct gateway to buyers actively searching for surplus inventory. Unlike traditional sales channels where you’re vying for attention, these platforms connect you with businesses specifically looking for excess stock. This targeted approach not only speeds up the liquidation process but also helps you avoid the deep discounts often required in broader sales environments.

These platforms typically see high buyer engagement, which can lead to significantly better conversion rates. To make the most of them, focus on optimizing your product listings and communication strategies.

Create Better Product Listings

Your product listing is often the first interaction a buyer has with your inventory, so it’s vital to make it count. Start with professional images that showcase your products from multiple angles, highlighting key details. A clear, visual representation can make all the difference.

In addition to visuals, write detailed descriptions that include all necessary information, such as specifications, dimensions, materials, and the current condition of the items. If your inventory is surplus due to overstock, seasonal changes, or discontinuation, be upfront about it. Transparency builds trust and reduces the chance of misunderstandings.

Pricing clarity is equally important. Display your prices prominently, including any additional costs like shipping or handling fees. If you offer volume discounts, make sure these are clearly outlined so buyers can see the benefits of ordering larger quantities.

For technical or unique products, consider adding videos to your listings. A short video can provide a closer look, helping buyers feel more confident about their purchase decision. Once your listings are optimized, the next step is engaging with buyers directly.

Talk to Buyers in Real-Time

One of the standout features of B2B marketplace platforms is the ability to communicate with buyers in real time. Use direct messaging to respond quickly, negotiate terms, and build rapport with potential buyers. Understanding their specific needs allows you to tailor your offers and secure bulk deals more efficiently.

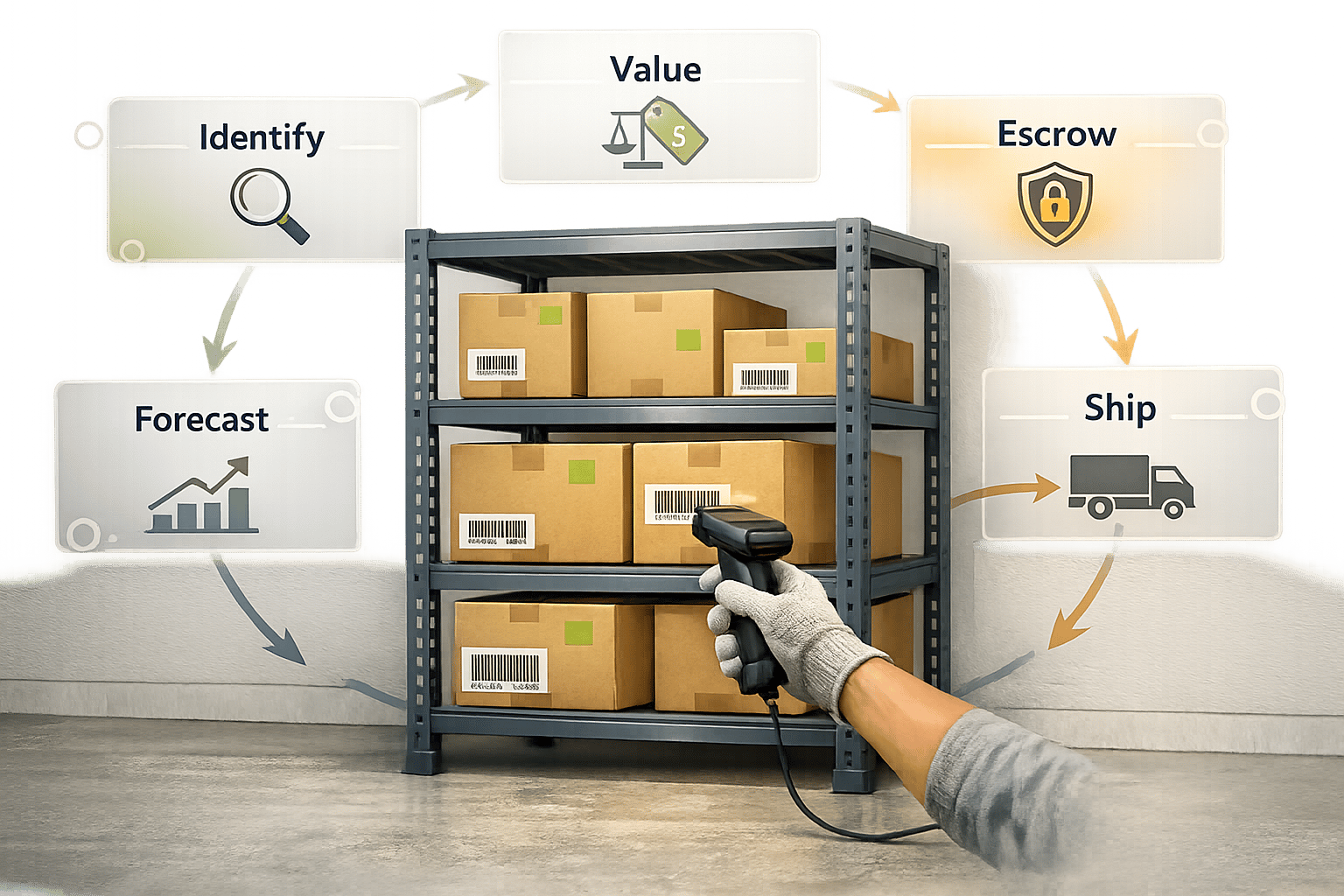

Use ForthClear's Tools for Bulk Sales

ForthClear is a platform that offers a range of tools to simplify surplus inventory sales. Its secure escrow payment system is particularly beneficial for large transactions, providing peace of mind for both parties and fostering trust.

For businesses with extensive inventory, the CSV upload feature is a game-changer. Instead of manually creating listings for hundreds of products, you can upload your entire inventory database in one go, ensuring everything is visible to buyers instantly.

ForthClear also enhances credibility through its verified supplier program, which can make your listings more appealing. Additionally, its bulk pricing tools allow you to set up tiered discounts, encouraging larger orders. To help you track performance, ForthClear provides order tracking and analytics, giving you insights into which products are drawing the most interest. This data can guide your pricing and marketing adjustments.

With integrated tools like CSV uploads, escrow payments, verified supplier status, and real-time tracking, ForthClear streamlines bulk transactions. Sellers should note that the platform charges a 5% fee, along with a transaction fee of 2.9% + $0.30 per sale.

4. Work with Professional Liquidators

When time is tight, professional liquidators can quickly move large amounts of inventory. This approach can free up cash flow and cut down on storage costs, though it typically comes with lower returns. The key is choosing a partner with the right experience and a strong track record. A poor choice could result in lower recovery rates and unexpected expenses. Start by identifying liquidators who specialize in your industry.

Research Liquidation Companies

Look for liquidators who have expertise in your specific industry. Check references from their past clients to get an idea of how long the process takes, their recovery rates, and whether there are any hidden charges. Ensure they are properly licensed and follow state regulations, especially for regulated products. Always request quotes from at least three companies to compare options.

Review Liquidator Contracts Carefully

Once you've narrowed down your options, take time to review their contracts thoroughly. Understand how their fee structures work - whether they charge a flat fee, a scaled percentage, a split arrangement, or operate on a purchase-to-sell basis. Confirm that fees cover services like transportation, sorting, cataloging, and storage. It's also important to verify how and when payments will be made and how they determine the value of your assets.

Pay close attention to payment timelines. Many liquidators won’t pay you until after your inventory is sold, which can take months. If you need cash immediately, look for liquidators that offer partial advances or guaranteed minimum payments. Keep in mind, though, that these options may come with higher fees.

Negotiate for Better Returns

Provide detailed information about your inventory and negotiate fee structures based on performance rather than just upfront costs. Compare options like split fees versus purchase-to-sell arrangements, depending on your cash flow needs. Stay involved in the process by requesting regular updates and progress reports.

Instead of focusing solely on the lowest fees, aim for the best overall return. For example, a liquidator charging 15% but achieving a 60% recovery rate could be a better choice than one charging 10% but only recovering 40%. Evaluate their network, marketing skills, and overall track record. Consistent communication is critical - regular check-ins help ensure your inventory gets the attention it needs and allow you to address any issues quickly.

Working with professional liquidators can be a smart way to turn excess inventory into immediate cash flow, but success depends on choosing the right partner and staying engaged throughout the process.

sbb-itb-bc600a0

5. Try Different Sales Channels

Clearing out excess inventory often means branching out beyond your usual sales avenues. Exploring alternative sales channels can open doors to new customer bases and markets that might have a demand for products you’re struggling to move. The goal is to find buyers who see value in what you have, even if your primary audience doesn’t. These additional channels can complement your existing efforts and help you reach untapped segments.

Target Related Markets

Sometimes, the key to moving surplus inventory lies in thinking outside the box. Your products might be valuable to industries or markets you haven’t considered yet. For example, the average small U.S. store holds around $48,000 worth of excess stock, making up 22% of their overall inventory. That’s a lot of potential just sitting there.

Start by identifying industries that could benefit from your products in unexpected ways. Electronics, for instance, might be useful for repair shops, educational programs, or businesses equipping remote workspaces. Selling locally can also help reduce transportation costs and improve profit margins. Plus, retaining local customers is far more cost-effective than acquiring new ones - it’s estimated to be five times cheaper.

You can also explore partnerships with other businesses that could cross-sell your products. By leveraging their platforms and customer base, you can extend your reach without the hefty costs of building a new audience from scratch.

"We've developed strong relationships with our vendors who will allow swaps. They don't want products sitting on the floor for too long, and obviously, we don't, either. So we work hand-in-hand and try to find a way out." - Ofir Farahan, Owner of OFY

Look at International Sales Options

If domestic markets aren’t cutting it, international sales might be the answer. Global markets often operate on different cycles and have unique consumer preferences, which means your surplus inventory could still be in demand abroad. For instance, products considered outdated in the U.S. may still be relevant and desirable in other regions.

Seasonal differences also play a role. Fashion items that didn’t sell during a U.S. summer might find eager buyers in countries just entering their warmer months. Similarly, technology products being phased out domestically could still hold value in emerging markets.

B2B marketplaces make it easier to connect with international buyers. These platforms allow you to showcase your inventory with detailed descriptions, helping potential buyers evaluate your offerings. Many of these marketplaces even offer free product listings, providing global exposure without significant upfront costs.

Work with Resale and Secondary Market Networks

Another effective way to move surplus inventory is by tapping into resale and secondary market networks. These networks specialize in finding buyers for excess stock, often through discount retailers or outlet stores. They know how to position and price your products to attract budget-conscious shoppers.

Resellers often focus on specific product categories, giving them valuable insights into where your inventory will sell best. By working with these partners, you can recover cash, while they grow their business and buyers enjoy quality products at discounted prices.

When choosing a resale partner, consider factors like their existing network, how quickly they can move your inventory, and the recovery rates they offer. You’ll also need to decide whether consignment or outright purchase works better for your financial situation and risk tolerance. Building a solid relationship with these networks can be a game-changer when similar inventory challenges arise in the future. By diversifying your sales channels, you can turn surplus stock into cash more efficiently.

6. Use Online Auction Methods

Online auctions have become a popular choice for businesses aiming to offload excess inventory quickly while potentially achieving better prices than traditional liquidation methods. The competitive nature of bidding often leads to higher returns, especially when multiple buyers find value in your offerings. In fact, auctions can boost recovery rates by up to 30% compared to older methods and cut selling time in half.

What makes online auctions so effective is their efficiency. Instead of negotiating with buyers individually, the auction process lets the market decide the value of your items through competitive bidding. This not only saves time but often results in higher sale prices compared to private transactions. It’s a strategy that complements other liquidation methods by tapping into market dynamics.

Pick the Right Auction Platform

Selecting the right auction platform is critical to your success. With the global online auction market expected to reach $55.95 billion by 2033, there are plenty of platforms to choose from, but not all cater to the same types of buyers or markets.

For businesses selling in bulk, focus on platforms that specialize in B2B sales and attract serious buyers. These platforms often come equipped with tools like advanced catalog management, detailed product descriptions, and integrated payment and logistics options.

Also, consider the platform’s reach. Some cater to regional markets, while others have a global audience. Online auctions offer broad exposure, which is especially useful if your inventory has international appeal or if domestic demand is limited.

Look for platforms with real-time bidding features and instant feedback. These tools enhance transparency and keep buyers engaged, increasing the likelihood of competitive final bids. The right platform sets the stage for organizing your inventory into effective auction lots.

Group Auction Lots Effectively

Once you’ve chosen a platform, the next step is organizing your inventory to maximize bidder interest. Depending on your buyer base, you can sell everything as a single lot or break it into smaller, targeted groups.

Grouping items by category is a smart way to appeal to specific buyer segments. For instance, if you’re selling electronics, office supplies, and clothing, creating separate lots for each category can attract buyers specializing in those areas.

Lot size also matters. Smaller lots might appeal to local retailers or small business owners, while larger lots - like truckload quantities - can draw in wholesale distributors and big resellers. Offering a range of lot sizes, from single pallets to truckloads, ensures you’ll attract a diverse group of buyers.

For lower-value items, consider bundling them together. Combining smaller items into a single lot can make them more appealing and generate higher bids. This strategy works particularly well for items that might not attract much attention on their own.

Set Realistic Minimum Prices

After organizing your inventory, setting a realistic reserve price is critical to achieving a successful auction. A reserve price is the minimum amount you’re willing to accept for an item. Balancing quick cash recovery with realistic market values is key to setting effective reserve prices.

Start by researching current market trends and historical auction data for similar items. This research helps you gauge achievable prices and set reserves accordingly [64,66]. Remember to account for auction fees, advertising costs, and commissions, which can range from 20% to 35%, depending on the item’s value [63,67].

"A reserve price is the minimum amount that a seller is willing to accept for an item in an auction, ensuring that the item is not sold for less." - Investopedia

A good rule of thumb is to set reserves at 50–75% of the estimated value. This range offers a safety net while still encouraging competitive bidding. Keep in mind that setting reserves too high can discourage participation.

Finally, consider the condition of your items when setting reserve prices. Excess inventory often includes returned, refurbished, or slightly damaged goods, so adjust your expectations accordingly. Transparency about reserve prices can also build trust with buyers and encourage serious participation.

7. Use Better Inventory Management Practices

Dealing with excess inventory is one thing, but the real game-changer is preventing it from happening in the first place. Accurate forecasting can cut inventory costs by 20% to 50%, making smarter inventory management a must for any business aiming to boost profitability.

To keep your inventory balanced and cash flow healthy, focus on three core strategies: demand forecasting, inventory alerts, and regular clearance cycles.

Use Demand Forecasting Tools

Modern demand forecasting tools tap into your sales data, market trends, and customer behavior to predict what you'll need. The payoff? Companies using demand planning models report a 20% cost reduction and a 10% revenue boost.

The best forecasts consider a variety of factors: historical sales trends, seasonal patterns, promotional effects, and external influences like economic shifts or competitor activities. AI-powered demand planning has improved forecasting accuracy by 30-50% for some companies.

"Demand forecasting is the cornerstone of effective inventory management." - Tompkins Solutions

Big names like Procter & Gamble and Amazon demonstrate the power of this approach. Procter & Gamble uses machine learning and analytics to align production with actual demand, cutting inventory levels by 15%. Similarly, Amazon leverages machine learning to analyze purchasing patterns, search trends, and seasonal shifts, improving fulfillment accuracy and reducing both excess inventory and shipping costs.

An ERP system can streamline this process by automatically tracking trends and flagging overstock risks. Historical trend analysis alone can improve forecast accuracy by 15-20%.

Set Inventory Level Alerts

Once you've nailed demand forecasting, automated alerts can keep you one step ahead. These alerts act as a safety net, signaling when stock levels hit critical thresholds. This way, you can avoid both stockouts and overordering by making timely, informed decisions.

To calculate reorder points, consider supplier lead times, average daily usage, and safety stock. For example, if you sell 50 units per day, have a 10-day lead time, and keep 5 days' worth of safety stock, your reorder point would be 750 units.

Not all inventory is created equal, so set different alert levels based on the type of product. Fast-moving items might need stricter monitoring, while slow-moving ones can afford more flexibility. Start by focusing on high-impact items - those that make up the bulk of your inventory's value or sales.

Forthcast allows businesses to customize alert settings, tailoring notifications to specific needs like customer service level. Regularly updating reorder points to reflect changes in the market or supply chain can also make a big difference. Companies that use supply chain forecasting tools report a 10-20% productivity boost.

Plan Regular Inventory Clearance Cycles

Instead of letting excess inventory pile up, schedule regular clearance cycles. This proactive approach helps you tackle potential problems before they escalate into major liquidation events, ensuring a seamless transition from forecasting to action.

For example, one retailer reduced slow-moving SKUs by 20%, freeing up $150,000 in working capital. They achieved this by conducting quarterly reviews to identify underperforming products early on.

Cycle counting is another effective strategy. Fast-moving items can be counted monthly, medium-velocity products quarterly, and slow-moving stock twice a year. This method provides accurate data without disrupting daily operations.

"Many companies perform regular physical inventory counts as part of their yearly financial accounting practices. Large companies with thousands of items typically halt operations for up to a week or more to perform a full physical inventory count. Cycle counting is an inventory management option that allows you to count items in a designated area of the warehouse without stopping operations to perform a complete physical inventory." - Bill Conway, NetSuite Practice Director, Blue Horseshoe Solutions

Top-performing companies audit their inventory quarterly, comparing results against sales trends and overall inventory costs. Use these audits to spot patterns - such as consistently underperforming products, seasonal surpluses, or suppliers with inconsistent lead times.

Track your progress and document what works. By monitoring key performance indicators like stock levels and inventory turnover, businesses can refine their clearance strategies. One e-commerce brand reduced customer dissatisfaction by 40% by keeping stock levels aligned with demand while cutting down on excess inventory.

Adopting these practices not only prevents future overstock but also strengthens your bottom line. Effective demand planning alone can lower inventory holding costs by an average of 25%, making these strategies a smart investment for long-term success.

Conclusion: Turn Excess Inventory Into Profit

Excess inventory doesn’t have to drain your resources or take up valuable space. The strategies we’ve outlined offer a practical way to transform surplus stock into recovered value and improved profitability.

In 2023, American retailers faced a staggering $740 billion worth of excess goods to liquidate. With stakes this high, the potential for turning challenges into opportunities is immense.

Successful businesses don’t rely on a single solution. They analyze slow-moving inventory, run targeted promotions, offer bulk discounts, and leverage advanced platforms to streamline bulk sales.

"Inventory liquidation isn't just about damage control - it's about smart supply chain management. Done right, it reduces waste, recovers value, and sharpens your inventory strategy." - Megaventory

Expanding your sales channels can further speed up the liquidation process. Professional liquidators and auction platforms offer quick solutions when direct sales slow down. While these methods provide immediate cash flow, solid inventory management helps prevent future overstock. Companies with accurate demand forecasting are 10% more likely to grow their revenue annually.

Proactive inventory management ties everything together. It’s not just about clearing out the excess - it’s about building a more efficient and profitable operation. Businesses that adopt proactive strategies can see a 20–30% drop in holding costs, alongside a 2–5% increase in gross margins and a 10–15% improvement in cash-to-cash cycle times. Tools like demand forecasting, inventory alerts, and regular clearance cycles don’t just solve today’s problems - they prepare your business for tomorrow’s challenges.

"Inventory liquidation is not only about clearing surplus inventory; it is a strategic necessity for businesses to optimize resources and maintain financial soundness." - Dynamic Distributors

Take a close look at your current inventory, identify what needs to move, and choose the liquidation methods that align with your products and goals. Whether you’re bundling slow-moving items with bestsellers, working with trusted liquidation marketplaces, or refining your forecasting systems, every step helps you unlock capital and streamline operations.

Your surplus stock isn’t just excess - it’s opportunity. With the right strategies and tools, you can turn today’s challenges into tomorrow’s competitive edge.

FAQs

What should I look for when selecting a professional liquidator to sell excess inventory?

When selecting a professional liquidator, it's crucial to prioritize their experience within your industry and their ability to manage your specific type of inventory. Look for someone with a solid track record and a reputation supported by references you can trust. Transparency is equally important - make sure their fee structure is clear, detailing costs for services like marketing and asset recovery upfront.

You’ll also want to assess their marketing reach and network. A liquidator with strong promotional capabilities can help ensure your inventory gets the attention it needs. Additionally, consider their adaptability in employing various sales strategies, such as auctions or direct sales, to suit your situation. Finally, don’t overlook their efficiency - if freeing up cash flow quickly is a priority, their speed in handling the liquidation process will be key. By focusing on these elements, you can choose a liquidator who delivers results without unnecessary delays.

How can businesses use online auctions to quickly and profitably sell excess inventory?

Businesses can take advantage of online auctions to turn excess inventory into profit by leveraging the competitive nature of bidding. The first step is to assess your inventory and organize items based on their condition and value. This will help you decide whether to sell items individually or in smaller bundles, making them more appealing to a diverse group of buyers.

Set reserve prices thoughtfully - high enough to protect your bottom line but low enough to spark interest and encourage bids. Timing matters, too. Schedule your auctions during peak buying periods when demand is at its highest. Selecting a trusted auction platform that aligns with your target audience can also significantly boost visibility and attract serious buyers. Lastly, emphasize the eco-friendly advantages of reselling unused items, which can resonate with environmentally conscious buyers and increase your auction’s appeal.

How can I avoid overstock and improve inventory management in my business?

To keep overstock in check and streamline inventory management, start with accurate demand forecasting. By predicting what customers are likely to need, you can adjust inventory levels to match demand more closely. This not only reduces excess stock but also ensures better cash flow.

Another effective approach is adopting a just-in-time (JIT) inventory system. With JIT, you order items only when they’re needed, which cuts down on holding costs significantly. Pair this with regular inventory audits and cycle counts to pinpoint slow-moving products. Once identified, these items can be discounted or bundled to clear out space and boost sales.

Lastly, invest in advanced inventory management software. These tools give you real-time insights into stock levels and sales trends, making it easier to make informed decisions and avoid future overstock issues. Together, these strategies create a more efficient and cost-effective way to manage your inventory.