AI is transforming supply chains by reducing waste and improving efficiency in circular systems. Traditional supply chains often generate excessive waste, but circular supply chains aim to reuse materials and keep resources in circulation. The challenge? Managing complex processes like returns, sorting, and reverse logistics. AI simplifies these tasks through tools like machine learning, computer vision, and optimization algorithms. Key benefits include:

- Demand Forecasting: AI predicts sales and returns, preventing overproduction and excess inventory.

- Sorting & Recycling: AI-powered systems sort materials with up to 93% accuracy, reducing landfill waste and energy use.

- Reverse Logistics: Smart routing and inspection tools streamline returns, saving costs and cutting emissions.

- Inventory Management: AI identifies surplus stock early and automates liquidation, turning waste into resources.

For example, Lenovo’s AI-driven refurbishment program improved efficiency by 116% and saved $100,000 annually. With global regulations like the EU’s Digital Product Passport on the horizon, AI is becoming a critical tool for businesses to stay efficient and compliant.

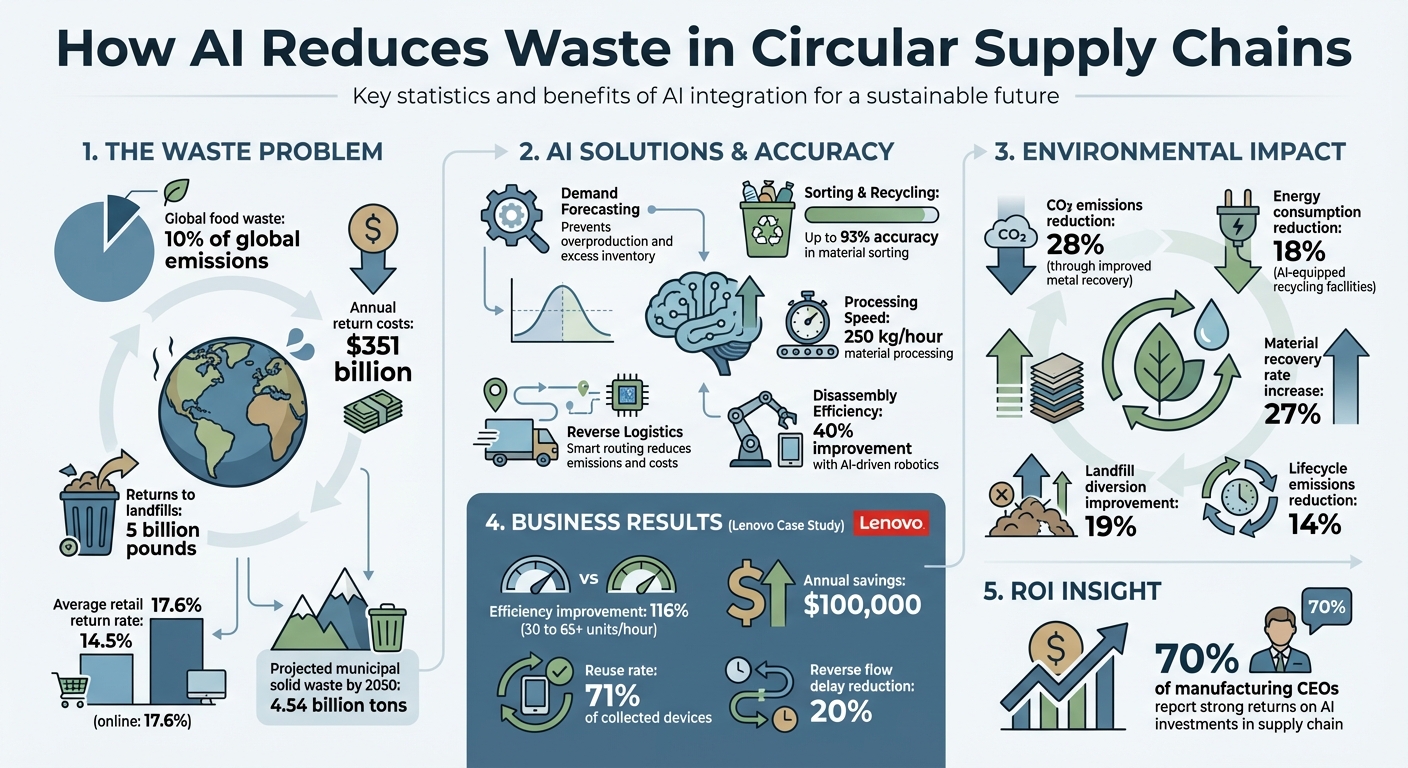

AI Impact on Circular Supply Chain Waste Reduction: Key Statistics and Benefits

Future of AI In Supply Chain and Circularity with Deborah Dull

How AI Reduces Waste Across the Supply Chain

AI is transforming the supply chain by addressing waste at every step - from product design to giving items a second life. By processing massive datasets in real time, AI spots inefficiencies that might otherwise go unnoticed and makes decisions to keep resources in circulation. Below, we’ll dive into how AI optimizes key areas of circular supply chains.

Predictive Demand Forecasting

AI-powered demand forecasting uses historical sales data, seasonal trends, weather predictions, and even local events to predict customer needs. This level of precision helps businesses avoid overproduction, which often leads to markdowns, excess inventory, and waste.

Take IKEA, for example. The company uses an AI tool to assess the quality of returned items, setting optimal secondary prices and deciding in real time whether to resell or donate them. This approach recovers value while cutting down on waste.

Forecasting isn’t just about predicting sales - it’s also about anticipating returns. Myntra, an Indian fashion e-retailer, employs deep neural networks to predict the likelihood of a customer returning a product. By analyzing browsing and shopping cart behaviors, the system flags potential returns before they happen. This allows the company to take proactive steps, like offering tailored discounts or marking certain items as non-returnable, thereby reducing the burden of reverse logistics.

"AI is emerging as a powerful tool for businesses to reduce waste in their supply chains. It can help optimize processes, predict demand more accurately, and make data-driven decisions that minimize waste and improve efficiency." - Svante Göthe, Head of Sustainability, RELEX

The environmental and financial implications are massive. Food waste alone accounts for nearly 10% of global emissions, and 70% of manufacturing CEOs report strong returns on AI investments in supply chain and procurement areas. Retailers and producers can also collaborate by sharing AI-driven insights, reducing the risk of overproduction for products with long lead times.

AI-Powered Sorting and Recycling

Beyond forecasting, AI revolutionizes how post-use materials are handled. Tools like Convolutional Neural Networks (CNNs) and computer vision systems can sort materials - plastics, metals, paper - with 93% accuracy, categorizing high-value components faster and more reliably than manual efforts. These systems can process up to 250 kg/hour.

Hyperspectral imaging takes things further by analyzing chemical compositions to sort polymers and identify contaminants. For complex items like smartphones or circuit boards, AI-driven robotic systems use deep reinforcement learning to adjust disassembly paths on the fly, boosting efficiency by 40% and recovering valuable components.

"AI-enabled vision systems demonstrate rapid and accurate classification of e-waste components, while ML-based algorithms can streamline disassembly sequences, enhance logistics, and improve forecasting." - Kartik Bhardwaj, Department of Computer Science and Information Technology

The environmental upside is striking. Improved recovery of high-value metals through AI sorting can cut CO2 emissions by 28%, while AI-equipped recycling facilities report an 18% reduction in energy consumption compared to manual methods. With municipal solid waste projected to hit 4.54 billion tons by 2050, contributing to 2.38 billion tons of CO2-equivalent emissions, these advancements are critical.

Optimizing Reverse Logistics

Managing returned products is one of the trickiest parts of a circular supply chain. In 2023, the average retail return rate hit 14.5%, with online purchases reaching 17.6%. These returns cost businesses more than $351 billion annually, with about 5 billion pounds of returned goods ending up in landfills.

AI is changing the game by making reverse logistics as efficient as forward logistics. Machine learning models analyze past sales, seasonality, and consumer behavior to predict return volumes, helping businesses prepare labor and warehouse capacity for refurbishing. Once items arrive, AI vision systems inspect them via high-resolution images to determine whether they should be resold, repaired, or recycled.

The real magic happens in routing. AI algorithms evaluate factors like processing center capacity, labor costs, and distance to decide the best destination for each return - whether it’s a store, refurbishment center, or recycling facility. This smart routing reduces transportation emissions while recovering as much value as possible. By feeding refurbished items back into the supply chain, businesses cut waste and reduce the need for new materials.

AI also helps detect return fraud by identifying anomalies in transactions and customer behavior. This ensures legitimate returns are processed efficiently, while fraudulent ones are flagged. The result is a closed-loop inventory system where refurbished stock meets future demand, cutting costs and minimizing waste.

Improving Inventory Management with AI

AI isn't just making waves in reverse logistics - it’s also reshaping how businesses manage inventory. By pinpointing surplus stock early and automating liquidation processes, AI helps tackle one of the biggest challenges in inventory management: dead stock.

Automated Surplus Detection

AI-powered inventory tools dive into historical sales data, seasonal trends, and consumer behavior to identify slow-moving products before they start piling up. For instance, items sitting unsold for over 60 days are flagged, providing businesses with a clear signal to act. Unlike traditional manual methods, AI continuously monitors every SKU and uncovers bigger trends that might escape human notice.

The benefits are hard to ignore. AI automates stock replenishment and aligns inventory levels with demand, cutting down on overstock and unnecessary markdowns. This is particularly valuable for seasonal items. Take pumpkins, for example - 1.5 billion pounds are grown annually in the U.S., but most end up wasted after the Halloween season. AI can adjust pricing in real-time during the season, ensuring products sell before their relevance fades.

But AI doesn’t stop at forecasting. It also powers closed-loop inventory optimization, which involves using refurbished or returned stock to meet future demand instead of sourcing new materials. For some SKUs, AI can predict scenarios where refurbished inventory fulfills over 10% of forward demand for the next quarter. This not only cuts procurement costs but also reduces waste, turning dead stock into valuable resources and strengthening the circular supply chain.

Using ForthClear for Surplus Liquidation

Once surplus stock is identified, quick liquidation is key. Enter ForthClear, a B2B marketplace that automates the process of selling excess inventory while ensuring secure transactions. Seamlessly integrated with Shopify, ForthClear can auto-detect dead stock - products unsold for 60+ days - and list them for sale in just a few clicks.

ForthClear takes the hassle out of liquidation. Its bulk upload tool paired with auto-image search eliminates manual effort, speeding up the process of finding buyers. The platform connects sellers with verified bulk buyers, ensuring surplus and returned items avoid landfills and find a second life.

Security is a top priority. ForthClear uses Stripe-powered escrow payments, holding funds until delivery is confirmed or 14 days have passed. This ensures a safe experience for both buyers and sellers. Plus, there are no upfront costs - it’s free to list items, and sellers only pay a 5% platform fee upon a successful sale.

"ForthClear has revolutionized how we handle excess inventory. The secure payment system and quality suppliers have made our sourcing process incredibly efficient." - Gordon Belch, Co-founder, vybey

For businesses with global operations, ForthClear simplifies international sales with built-in tariff estimates, making it easier to connect with buyers worldwide. The platform also supports tiered bulk pricing, enabling sellers to offer discounts for larger orders (like "Buy 50+ get 20% off") to recover capital more effectively. With real-time messaging for negotiations and a network of verified buyers, ForthClear transforms surplus liquidation into a streamlined, automated process that aligns with the principles of circular commerce.

sbb-itb-bc600a0

Measuring AI's Impact on Waste Reduction

AI's role in circular supply chains is undeniable, but to truly understand its effectiveness, tracking specific metrics is critical. These metrics not only validate AI's contribution to reducing waste but also highlight its ability to streamline operations in a circular supply chain.

Key Metrics to Track

Some key metrics offer clear insights into AI's impact:

- Material recovery rate: AI can boost recovery rates by up to 27%.

- Landfill diversion rate: Waste diverted from landfills improves by 19%.

- Lifecycle emissions reduction: Emissions see a reduction of 14%.

Operationally, AI also delivers measurable improvements:

- Reverse flow delay reduction: AI can accelerate returns processing, improving logistics efficiency by about 20%.

- Refurbished inventory utilization rate: AI identifies where refurbished stock meets 10% or more of quarterly demand, reducing reliance on new procurement.

- Returns volume accuracy: AI forecasting aligns warehouse capacity with actual returns, preventing bottlenecks and improving overall efficiency.

"AI is no longer just a forward-supply-chain tool - it's the missing link in circularity." - Isabella Harrington, Supply Chain Expert

These metrics provide both statistical validation and operational improvements, underscoring AI's role in advancing circular supply chains.

Real-World Examples

A standout example comes from Lenovo's Mobile Business Group, which implemented an AI-driven refurbishment solution using edge computing, IoT sensors, and computer vision to automate inspections. Under the leadership of Aaron Zhang (ISSC Reverse, Repair, Refurbish Director) and Zhen Li (Senior Manager – Services Supply Chain Strategy), the initiative achieved remarkable results in just one year:

- 116% improvement in efficiency: Output rose from 30 to over 65 units per hour.

- $100,000 in annual savings: Refurbishment costs dropped significantly.

- 71% reuse rate: Most devices collected are refurbished or repurposed for parts, aligning with Lenovo's circular economy goals.

"Our AI solution greatly enhances human productivity, makes refurbishment work more rewarding by removing repetitive manual tasks, and can even help managers ensure robust safety procedures on the factory floor." - Aaron Zhang, ISSC Reverse, Repair, Refurbish Director, Lenovo

These advancements also align with regulatory requirements. The EU's Digital Product Passport (launching in 2026) and Extended Producer Responsibility (EPR) laws demand detailed circularity data, making AI-driven tracking not just beneficial but essential for compliance.

Conclusion

AI transforms circular systems by automating surplus detection, forecasting return volumes, and fine-tuning reverse logistics. It goes beyond simply moving products - it restores value while helping companies comply with stricter regulations, like the upcoming Digital Product Passport requirements in the EU.

With supply chains being a major source of emissions and the decarbonization market rapidly expanding, businesses must embrace smart solutions to stay competitive and compliant. Platforms such as ForthClear simplify surplus liquidation through secure transactions and low fees. By connecting production, usage, and recovery, AI ensures each cycle not only fulfills demand but also regenerates value.

From predictive forecasting to surplus management, starting small with proven AI tools can pave the way for larger transformations. For instance, businesses can use existing sales data to train basic AI models, integrate their Shopify store to automatically detect unsold inventory, or analyze simple data logs to identify bottlenecks in reverse logistics.

These improvements highlight the deeper impact AI has on modern supply chains.

"AI is no longer just a forward-supply-chain tool - it's the missing link in circularity." - Isabella Harrington, Supply Chain Expert

The real challenge isn’t deciding whether to adopt these tools but determining how quickly they can be implemented to achieve sustainable efficiency.

FAQs

How does AI help predict demand and reduce waste in circular supply chains?

AI plays a crucial role in forecasting demand within circular supply chains by examining historical sales data, identifying market trends, and evaluating other essential factors. This allows businesses to predict customer needs with greater precision and make real-time adjustments to production or inventory levels.

By matching supply closely with actual demand, AI helps cut down on overstock, reduces waste, and supports just-in-time inventory practices. This method not only improves resource efficiency but also strengthens the sustainability of circular supply chain processes.

How does AI help streamline reverse logistics in circular supply chains?

AI is transforming reverse logistics, making it more efficient and precise while improving decision-making for handling returned, recycled, or refurbished products. It can forecast return trends, automate product inspections, and streamline sorting and recovery operations. This helps businesses cut waste, lower costs, and recover more usable materials.

AI-powered tools also assist companies in meeting regulatory requirements like Extended Producer Responsibility (EPR). These tools enhance forecasting, inventory management, and resource recovery, enabling businesses to build stronger, more sustainable circular supply chains. The result? Reduced environmental impact and better overall performance.

How does AI help businesses meet regulations like the EU’s Digital Product Passport?

AI helps businesses navigate regulations like the EU’s Digital Product Passport by making it easier to gather, verify, and share detailed product information. This includes specifics about materials, supply chain details, and environmental impact, ensuring companies meet legal standards while maintaining transparency.

Through automation, AI simplifies data management and analysis, allowing businesses to adapt to regulatory updates, minimize mistakes, and streamline reporting processes. Beyond compliance, this approach fosters trust with both consumers and partners by highlighting responsible and transparent practices.