Predictive analytics is transforming inventory management by using historical data, AI algorithms, and machine learning to forecast demand and reduce surplus stock. Unlike outdated methods, these tools provide real-time insights, helping businesses cut costs and improve efficiency.

Key Takeaways:

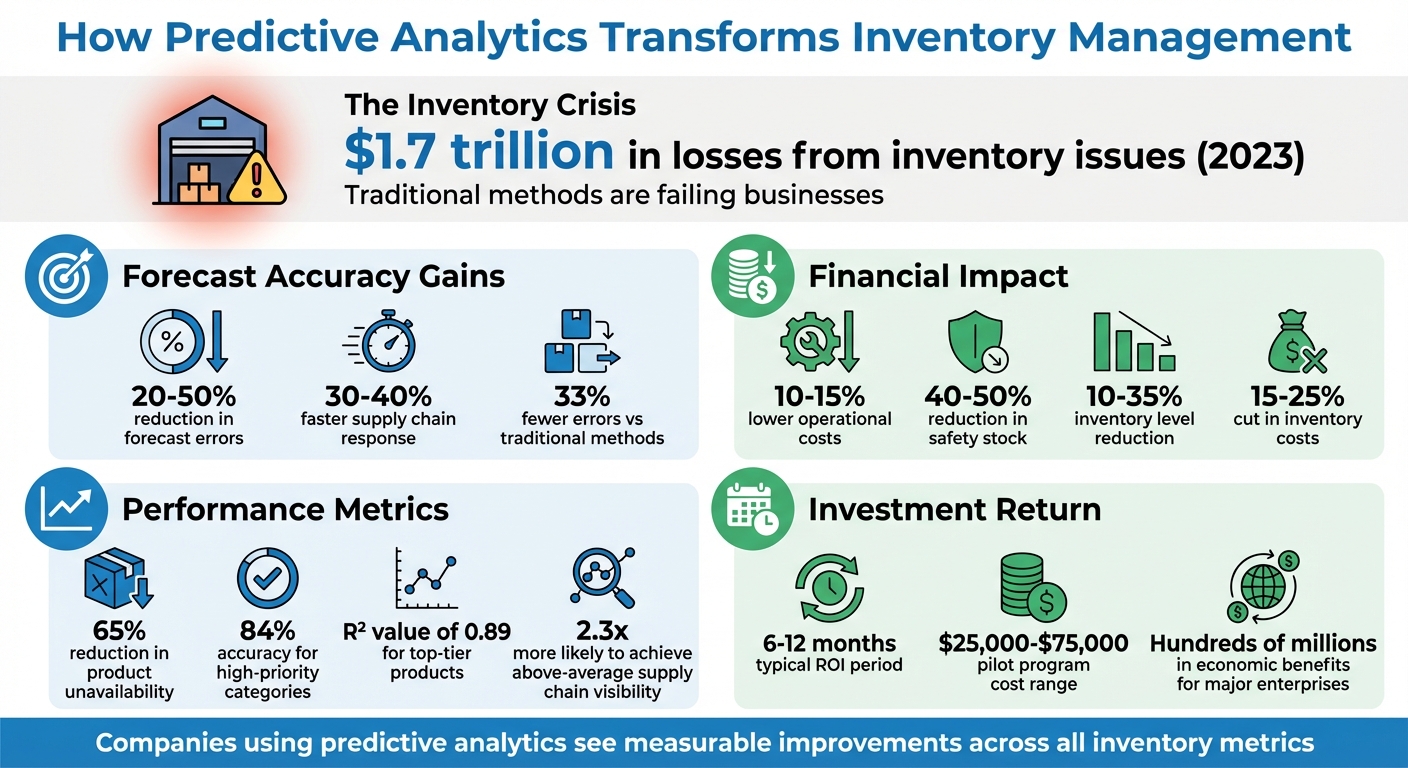

- $1.7 trillion in losses from inventory issues were reported in 2023.

- AI reduces forecast errors by 20-50% and speeds up supply chain responses by 30-40%.

- Businesses using predictive models see 10-15% lower operational costs and 40-50% less safety stock.

How It Works:

- Data Sources: Combines sales history, market trends, weather, and even social media data.

- Techniques: Uses advanced algorithms like RNNs, LSTMs, and regression models to predict demand.

- Results: Companies cut inventory levels by 10-35%, saving millions annually.

By identifying surplus risks early, automating replenishment, and enabling SKU-level forecasting, predictive analytics ensures smarter inventory decisions. This approach not only saves money but also prevents waste, making it a must-have for modern businesses.

Predictive Analytics Impact on Inventory Management: Key Statistics and Benefits

Can Predictive Analytics Optimize Stock Levels?

How Predictive Analytics Works for Surplus Inventory

Predictive analytics uses machine learning models to identify intricate patterns and improve forecasting accuracy by incorporating real-time data. This approach transforms inventory management from a reactive process into a forward-thinking strategy. These advanced tools form the backbone of the demand forecasting methods outlined below.

Anomaly detection algorithms play a critical role by spotting unusual sales patterns that could indicate shifts in demand or disruptions in supply. Meanwhile, scenario modeling allows managers to simulate different market conditions - like supplier delays or sudden demand surges - helping them craft contingency plans. As Hatim Kagalwala, Applied Scientist at Amazon, puts it:

"The adoption of AI and ML in demand forecasting is no longer a competitive advantage but a necessity in modern supply chain management".

Demand Forecasting Methods

Various algorithms address different forecasting challenges. Time series analysis relies on tools like Recurrent Neural Networks (RNN), Long Short-Term Memory (LSTM), and Exponential Smoothing to predict seasonal trends and recurring demand cycles. Regression models - including linear, non-linear, and logistic regression - help identify how changes in pricing affect demand volume. Machine learning approaches such as Random Forests, Decision Trees, and Support Vector Machines classify products into categories like "slow-moving" or "high-risk" for surplus. Additionally, deep learning with Artificial Neural Networks captures intricate consumer behavior and market dynamics.

These AI-driven forecasting techniques adapt to real-time changes in consumer behavior, reducing forecasting errors by 20% to 50% and cutting product unavailability by as much as 65%.

Data Sources That Drive Optimization

Predictive models achieve their accuracy by combining internal data - such as sales history, lead times, turnover rates, and inventory levels - with external data like economic trends, holiday schedules, competitor activity, weather conditions, and even social media sentiment. Companies using predictive analytics for inventory planning are 2.3 times more likely to achieve above-average supply chain visibility and efficiency. These systems pull data from various technologies, including ERP, WMS, POS, IoT sensors, and RFID tracking. Margaret Lindquist, Senior Writer at Oracle, highlights this advantage:

"AI's strength lies in its ability to crunch massive amounts of data rapidly, so that human demand forecasting specialists can focus on interpreting and communicating the results".

Research Findings: Results from Predictive Analytics

Measured Outcomes from Research

Companies that have embraced predictive analytics are seeing impressive results, particularly in managing inventory and related costs. For instance, businesses using multi-echelon inventory optimization (MEIO) alongside demand sensing have managed to cut safety stock levels by 40–50% without compromising customer service. This translates into reduced carrying costs and more efficient warehouse utilization.

In large-scale operations, applying a simulation-optimization framework has led to inventory reductions of 10–35%, generating economic benefits worth hundreds of millions of dollars for leading enterprises. Pawan Joshi, EVP of Products and Strategy at e2open, highlights the strategic impact:

"The research enables us to identify specific opportunities to increase resilience, particularly by leveraging AI-driven demand sensing to improve forecast accuracy, manage product assortment, and use multi-echelon inventory optimization to better manage stock levels in volatile times".

AI-driven demand sensing has also proven to be a game-changer, reducing forecast errors by 33% compared to traditional methods. This is particularly critical for slow-moving "tail" items, which make up 85% of inventories and are prone to a 21 percentage point increase in planning errors during periods of volatility. These findings are further supported by real-world case studies.

Case Studies: Business Applications

One notable example comes from a major FMCG company, which used gradient boosting models to predict inventory status with an R² value of 0.89 for its top-tier products. This level of precision allowed the company to proactively address overstock and understock issues for individual SKUs. Additionally, predictive classification models achieved accuracy rates of up to 84% for high-priority categories.

In the food and beverage industry, businesses have adopted AI-powered dynamic pricing models to manage perishable inventory more effectively. These systems automatically adjust prices as products approach their expiration dates, leveraging shelf-life prediction algorithms to estimate freshness. This not only reduces waste but also enables the redistribution of surplus items to secondary markets or charitable organizations. Given that the top 10% of items account for 75% of total sales, this strategy has been instrumental in managing surplus across product portfolios.

During the pandemic, when traditional forecasting methods faltered, AI-driven systems demonstrated resilience by incorporating real-time data from IoT sensors to maintain forecast accuracy, especially for slow-moving items.

Zhaoyang Larry Jin and his team at C3 AI documented their success:

"This approach has proven successful in reducing inventory levels by 10-35 percent, resulting in hundreds of millions of dollars of economic benefit for major enterprises at a global scale".

sbb-itb-bc600a0

How to Implement Predictive Analytics for Surplus Stock

Automated Replenishment and Inventory Alerts

Start by setting up your system to monitor stock levels in real-time and automatically trigger purchase orders when inventory reaches dynamic reorder points. Unlike outdated static safety stock rules, modern predictive tools adjust thresholds based on factors like demand velocity, lead time variability, and sales trends. This means your system should constantly recalculate buffer levels using live data.

For example, in June 2025, Five Below Inc. rolled out Invent.ai across its 1,800+ stores. The tool generated probabilistic forecasts for millions of product–store combinations by factoring in seasonality and location-specific variables. Graham Poliner, the company’s Chief Strategy Officer, noted:

"Invent.ai has been a game-changer for our operations".

Additionally, configure anomaly detection to flag unusual demand drops or unexpected sales patterns. Tools like Prediko can help identify at-risk SKUs early, allowing you to act quickly. Set up automated alerts for anomalies or shipment delays to stay ahead of potential issues.

Once you’ve established this foundation, refine your strategy with SKU-level forecasts and scenario planning.

Scenario Planning and SKU-Level Forecasting

Dive deeper by implementing detailed SKU-level forecasts. This means assessing demand for specific product variants - like size, color, or style - to avoid stocking mismatches. A great example of this approach is Asia's largest spice company, which used ConverSight's "Athena" AI to achieve a 30% improvement in forecast accuracy, reduce inventory waste by 20%, and cut planning computation time in half.

Take it a step further with "what-if" simulations to test how your inventory strategies hold up under various scenarios. For instance, model situations like a 10% demand surge, a two-week shipping delay, or the impact of a sudden promotional campaign. This proactive approach lets you prepare contingency plans instead of scrambling to react later. According to research, companies using predictive analytics for inventory planning are 2.3 times more likely to achieve above-average supply chain visibility and efficiency.

To get started, pilot predictive analytics with a small set of SKUs - such as fast-moving, slow-moving, or seasonal items. Standardize your data by normalizing SKUs across platforms like Shopify, WMS, and ERP. Make sure to fill in missing supplier lead times to ensure forecasts are reliable.

Once your forecasts are fine-tuned, ensure they’re seamlessly integrated with your e-commerce platforms.

Connecting with E-commerce Platforms

Integrating your e-commerce platform is key to maintaining accurate forecasts. Tools designed for platforms like Shopify can automatically sync sales, POS, and warehouse data. For instance, ForthClear's Shopify integration flags products unsold for over 60 days as surplus.

When slow-moving inventory is identified, ForthClear simplifies liquidation. Merchants can list surplus items within minutes, syncing directly with verified bulk buyers. Transactions are secured through Stripe escrow, with a flat 5% fee charged on successful sales.

To get the most out of your predictive analytics tools, ensure they aggregate data from all relevant systems - e-commerce platforms, POS systems, WMS, ERP, and marketing tools - via API integrations. Predictive models require 12–24 months of historical transaction data to accurately capture trends and deliver actionable insights.

Conclusion: Why Predictive Analytics Makes Sense for Surplus Inventory

Predictive analytics can cut inventory costs by 15–25% and reduce stockout-related revenue losses by 7–12% of annual revenue - significant savings for any business. Take predictive route optimization, for example: it has helped companies save hundreds of millions of dollars every year.

Beyond the financial perks, predictive analytics boosts operational stability. By shifting from reactive to proactive management, businesses can pinpoint potential issues weeks ahead of time. This ensures smoother warehouse operations, smarter storage allocation, and fewer surprises. Plus, these efficiencies help lower the environmental impact of inventory management.

Speaking of the environment, predictive analytics addresses a critical problem: excess inventory. Stocking only what customers truly need prevents overproduction and waste, tackling inefficiencies that led to trillions in losses during 2023. By avoiding obsolete or unsellable products, companies not only save money but also contribute to a more sustainable supply chain.

The financial return is equally impressive. Most businesses recover their investment within 6–12 months, with pilot programs typically costing between $25,000 and $75,000. Tools like ForthClear take this a step further, simplifying surplus liquidation by connecting sellers with verified bulk buyers through secure escrow systems.

Shifting to proactive inventory optimization isn’t just a smart move - it’s becoming the new norm. In today’s unpredictable markets, this approach helps businesses minimize waste, maximize efficiency, and stay ahead of the competition.

FAQs

How can predictive analytics help businesses reduce surplus inventory?

Predictive analytics uses AI to dig into real-time sales trends and predict demand with impressive precision. By spotting patterns in customer buying habits, it helps businesses fine-tune production schedules and reorder points, ensuring they maintain just the right amount of stock.

It also highlights slow-moving products early on, giving companies a chance to take action - whether that's running promotions or redistributing inventory. This smarter approach can slash surplus inventory by up to 40%, reducing costs, cutting waste, and boosting overall efficiency.

What data is needed for accurate demand forecasting with predictive analytics?

Accurate demand forecasting with predictive analytics hinges on blending internal and external data to create a clearer picture of future needs. Internally, elements like historical sales records, seasonal patterns (such as holiday spikes or promotional periods), and inventory specifics - including stock levels and lead times - are essential. Adding pricing and promotional data helps gauge how discounts or campaigns might sway customer behavior.

On the external side, factors like real-time sales trends, weather patterns, and economic indicators provide valuable insights into the larger market landscape. By examining these datasets together, AI-driven models can identify trends, quickly adapt to short-term changes, and deliver accurate demand forecasts. This allows businesses to make smarter inventory decisions, reducing excess stock and boosting overall efficiency.

How can predictive analytics save costs and benefit the environment in inventory management?

Predictive analytics driven by AI offers a powerful way to cut down on the costs tied to surplus inventory. With advanced forecasting models, businesses can reduce overstock levels by an impressive 30–40%. This not only frees up cash but also slashes carrying costs, which typically eat up 20–30% of inventory budgets. Some companies using these tools have seen up to a 40% drop in surplus stock, recovering as much as 11% of their annual revenue that was previously tied up in unsold goods.

The positive impact extends beyond finances. Improved demand forecasting means less waste, as fewer unused products end up in landfills. By syncing production with real-time demand, businesses also lower the carbon footprint associated with storage and transportation. These efficiencies align with sustainability efforts, such as reuse and recycling, while helping companies meet U.S. environmental targets - and boost their bottom line at the same time.