Inventory management is a balancing act: order too much, and you’re stuck with excess stock; order too little, and you lose sales. The solution? Data-driven planning. By using real-time data, predictive analytics, and demand forecasting, businesses can cut stockouts by up to 65% and reduce inventory levels by 20-30%. This approach minimizes waste, lowers costs, and improves cash flow, unlike traditional methods that rely on guesswork and spreadsheets.

Key Takeaways:

- Inventory waste happens due to overstocking, dead stock, or obsolete items, leading to high carrying costs (25-30% of inventory value) and lost revenue.

- Data-driven planning uses tools like predictive analytics, real-time tracking, and demand forecasting to optimize inventory and reduce waste.

- Businesses using data-driven methods see benefits like lower holding costs, fewer stockouts, and improved customer satisfaction.

- Tools like ForthClear help manage surplus inventory by connecting sellers with bulk buyers, turning excess stock into cash.

Switching to data-driven planning isn’t just about saving money - it’s about staying competitive in a fast-changing market.

The Inventory Balancing Act | Avoid Overstock & Stockouts with Data-Driven Planning

What is Inventory Waste?

Inventory waste refers to excess stock that remains unsold, tying up cash and taking up valuable warehouse space. This can include items that exceed demand forecasts, products that haven't sold for months (often called "dead stock"), or goods rendered obsolete by seasonal shifts, discontinued lines, or outdated technology. In the e-commerce world, inventory waste often arises from errors in forecasting, inconsistent ordering practices, or sudden changes in customer preferences. Tackling this issue requires targeted solutions tailored to the specific causes.

In industries like manufacturing and retail, 20% to 40% of inventory typically falls into the category of non-moving or dead stock. For e-commerce businesses, managing inventory becomes even trickier due to the sheer variety of products - each with unique lead times and demand patterns - that significantly increase the risk of waste. Adding to the challenge, 41% of businesses still rely on manual methods for inventory management, and 26% depend on spreadsheets, which often leads to inefficiencies and errors.

Types of Inventory Waste

Inventory waste can take on several forms:

- Excess inventory: This happens when businesses order more than they need, often due to overly optimistic forecasts or bulk purchasing decisions that seemed cost-effective at the time.

- Dead stock: These are items that no longer sell, whether because of damage, incorrect specifications, or loss of customer interest.

- Obsolete inventory: Products that are discontinued, out of season, or have undergone packaging changes fall into this category, making them difficult to sell at full price.

- Short-dated stock: For businesses handling perishable or time-sensitive goods, delays in turnover or supply chain issues can leave them with products nearing expiration.

Consequences of Inventory Waste

The financial impact of inventory waste goes far beyond the cost of the products themselves. It ties up working capital that could otherwise be invested in fast-moving goods. Warehouse space is also wasted, with annual carrying costs - covering storage, insurance, labor, and lost opportunities - accounting for 15% to 27% of inventory value.

When businesses try to clear out excess inventory, they often resort to heavy discounts, which eat into profit margins. Beyond the financial toll, inventory waste has environmental repercussions. The energy and raw materials used in manufacturing and transporting these goods are wasted, and unsold items frequently end up in landfills. Operationally, inventory waste clogs up supply chains, making it harder for businesses to adapt to changing market demands.

What is Data-Driven Inventory Planning?

Data-driven inventory planning takes the guesswork out of managing stock by leveraging real-time algorithms, predictive analytics, and big data. Instead of relying on traditional methods, businesses use advanced analytical tools to process large datasets, including historical sales trends and external factors like weather, holidays, and economic shifts. This approach moves away from "push-based" systems, which stock inventory based on anticipated demand, and shifts toward "pull-based" systems that respond to actual, real-time demand signals. This shift helps businesses become more agile and efficient in their operations.

By 2025, 75% of businesses will still depend on traditional methods, while only 40% will have adopted AI for inventory management. However, those that use AI-driven systems experience 20–30% higher revenue growth. On the flip side, supply chain disruptions cost businesses an average of $1.75 million annually due to inventory issues.

"The move towards data-driven inventory planning is crucial for retailers aiming to stay competitive in a challenging market environment."

– Management One

In 2025, Walmart implemented AI-based systems that reduced inventory costs by 25% and improved supply chain efficiency by 10%. Similarly, Maersk optimized its logistics with AI, cutting transportation costs by 15% and increasing delivery speed by 20%. These examples highlight how data-driven inventory planning transforms reactive management into a proactive strategy.

Core Principles of Data-Driven Planning

Data-driven inventory planning is built on three key principles:

- Predictive Analytics: Machine learning tools analyze historical data to identify patterns and forecast future needs. This helps businesses prepare for seasonal demand spikes and potential supply chain disruptions before they occur.

- Real-Time Inventory Tracking: Using IoT devices and RFID tags, companies can monitor product movement in real time. A centralized tracking system ensures inventory data is always up-to-date, giving managers a clear and immediate view across all channels for faster decision-making.

- Demand Forecasting: By incorporating external factors like weather, economic trends, and consumer behavior, demand forecasting aligns inventory levels with actual demand. This reduces overstocking and stockouts, enabling systems to operate with minimal human intervention.

Benefits of Data-Driven Planning

Adopting data-driven inventory planning provides businesses with several key advantages:

- Increased Accuracy: Automated systems reduce the likelihood of human errors. For example, when Australian hardware supplier Tradeware replaced manual spreadsheets with Netstock's predictive inventory solution in 2026, they were able to provide 12-month order forecasts to suppliers and optimize inventory across six warehouses.

- Reduced Overstock: Businesses can identify dead stock - products with no sales for over 60 days - and slow-moving items early. This allows them to adjust prices or halt reorders, freeing up capital and protecting profit margins by avoiding excessive discounting and stockouts.

- Better Customer Demand Alignment: Advanced systems that analyze multiple data streams help businesses anticipate changes in buying behavior rather than just reacting to past trends. During supply chain disruptions, real-time visibility enables companies to quickly identify weak points and make informed decisions, such as diversifying suppliers or building strategic stock reserves.

"Predictive inventory management breaks this cycle [of stock-outs] by applying advanced analytics to identify potential risks before they materialize."

– Netstock

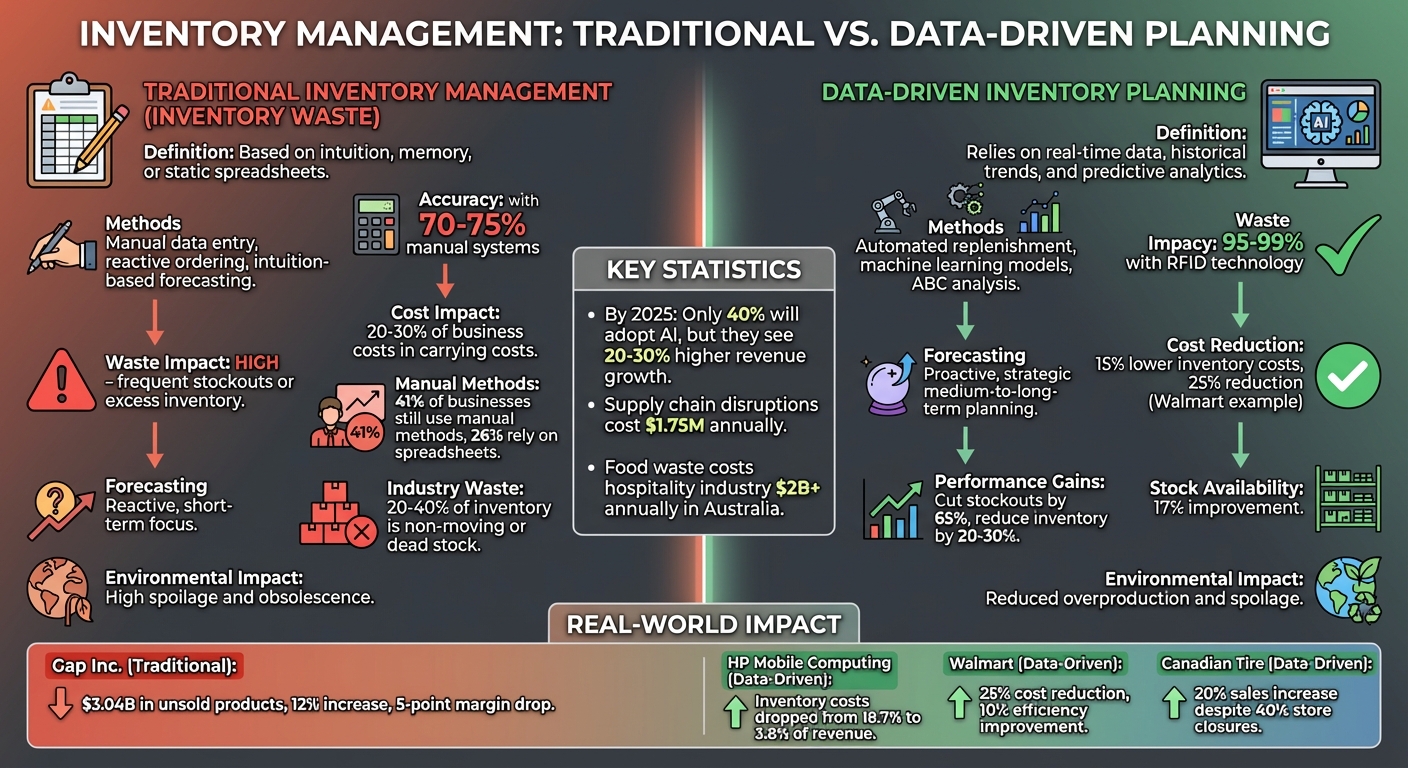

Key Differences Between Inventory Waste and Data-Driven Planning

Traditional vs Data-Driven Inventory Management: Key Differences and Impact

Traditional inventory management often relies on intuition, whereas data-driven planning uses a combination of historical and real-time data to inform decisions. The difference becomes clear in how businesses handle change: traditional methods are reactive, scrambling to address issues as they arise, while data-driven systems predict and prepare for shifts in customer behavior before they occur. This contrast ties back to earlier discussions about wasted resources and missed opportunities.

Another key distinction lies in process efficiency. Manual inventory management often results in fragmented data, where departments operate with inconsistent numbers. In contrast, data-driven planning integrates multiple data sources through automation, creating a unified and accurate data set. This eliminates inefficiencies that stem from disconnected processes.

"If you rely solely on inventory planning without demand forecasting, you're guessing instead of preparing. And guessing leads to waste, lost sales, and unnecessary costs."

– TapTouch POS

The financial impact of these approaches is also stark. Poor control in traditional methods can lead to massive losses - food waste alone costs the hospitality industry over $2 billion annually in Australia. Meanwhile, data-driven forecasting can reduce inventory costs by 15% and increase stock availability by 17%. Tools like ABC Analysis (categorizing inventory by value), Economic Order Quantity (EOQ), and precise reorder point calculations help businesses balance supply and demand effectively.

Here’s a quick comparison of these two approaches:

Comparison Table: Inventory Waste vs. Data-Driven Planning

| Aspect | Inventory Waste (Traditional Methods) | Data-Driven Inventory Planning |

|---|---|---|

| Definition | Based on intuition, memory, or static spreadsheets | Relies on real-time data, historical trends, and predictive analytics |

| Methods | Manual data entry, reactive ordering, intuition-based forecasting | Automated replenishment, machine learning models, and ABC analysis |

| Waste Impact | High; frequent stockouts or excess inventory | Low; optimizes stock levels to meet customer demand |

| Cost Implications | High carrying costs (20–30% of business costs) and tied-up capital | Improved cash flow and reduced storage costs |

| Forecasting Approach | Reactive; short-term focus | Proactive; strategic medium-to-long-term planning |

| Environmental Effects | High spoilage and obsolescence, leading to waste | Reduced overproduction and spoilage, lowering environmental impact |

This comparison highlights how data-driven planning not only improves efficiency but also reduces waste and costs, making it a smarter approach for modern businesses.

sbb-itb-bc600a0

How Data-Driven Planning Reduces Inventory Waste

Data-driven planning shifts businesses away from unreliable guesswork and toward precise, informed decision-making. By analyzing factors like historical sales, seasonal trends, and external influences such as weather or economic conditions, businesses can forecast demand with far greater accuracy. This approach eliminates the guesswork that often leads to overstocking "just in case" or running out of stock at critical moments. In essence, it lays the foundation for strategies that directly tackle inventory waste.

Using predictive analytics can drastically improve inventory management. For example, it can cut stockouts by up to 65% while reducing overall inventory levels by 20–30%. Retailers who use RFID technology for real-time inventory tracking achieve accuracy rates of 95-99%, compared to the 70-75% seen with traditional manual systems. This level of precision reduces the need for excess stock and minimizes unsold items sitting in storage.

Several targeted techniques further address waste at its root. Statistical Safety-Stock Solvers use real supplier lead-time variability to calculate buffer stock, avoiding the "safety stock bloat" that often leads to waste. Dynamic reorder points adjust automatically based on demand fluctuations, ensuring stock arrives when it’s actually needed. Meanwhile, SKU rationalization identifies underperforming or redundant products, helping businesses phase out "dead stock" that occupies warehouse space and ties up resources.

Specific Strategies for Waste Reduction

Diagnostic analytics help uncover the reasons behind inventory imbalances. Tools like inventory health diagnostics flag surplus, shortages, and obsolete stock against company policies, allowing managers to address issues before they escalate into costly write-offs.

Multi-Echelon Optimization (MEIO) takes a broader view, balancing inventory across the entire supply chain, including warehouses, distribution centers, and retail locations. This prevents overstocking in one area while shortages occur elsewhere, ensuring inventory is allocated based on real-time needs.

Automated replenishment systems trigger orders based on how quickly products are selling. When paired with ABC/XYZ segmentation - which categorizes inventory by value and demand volatility - businesses can focus on high-impact items with tighter controls, while spending less time managing low-value stock.

A great example of these principles in action comes from Canadian Tire. During Q2 2020, despite having to close 40% of its retail locations due to the pandemic, the company managed a 20% increase in sales. Eddie Weekse, Manager of Merchandise Planning, led the adoption of ThoughtSpot, which unified previously siloed data sources. By moving away from intuition-based decisions to a data-driven strategy with real-time insights into customer behavior, Canadian Tire made smarter inventory decisions that aligned with shifting consumer demand.

When surplus stock is unavoidable, these data-driven strategies ensure it can still be handled effectively.

Real-World Example: Using ForthClear for Surplus Reduction

Even with the best planning, some surplus is inevitable - whether due to seasonal changes, product updates, or unexpected market shifts. Platforms like ForthClear offer a way to turn this surplus into an opportunity.

ForthClear’s Shopify App identifies products that haven’t sold in 60+ days, flagging them as surplus. Instead of letting these items waste valuable space and tie up capital, businesses can list them on ForthClear’s B2B marketplace with just a few clicks. The platform connects sellers with verified bulk buyers actively searching for surplus inventory in categories like electronics, apparel, and home goods.

The app’s bulk pricing feature allows sellers to set tiered discounts, such as "Buy 50+ units, get 20% off." This encourages larger purchases, helping clear out more inventory in a single transaction. By transforming excess stock from a liability into recovered capital, businesses can reinvest in faster-moving products and maintain a healthier inventory flow.

Pros and Cons of Data-Driven Planning and Inventory Waste Approaches

When it comes to managing inventory, businesses face a clear trade-off between traditional methods and data-driven approaches. Traditional inventory management relies on manual tracking and intuition, which keeps upfront technology costs low. This makes it an attractive option for small businesses with limited product lines. However, these savings often come at a hidden long-term cost. Businesses relying on traditional methods are more likely to face issues like obsolete stock, frequent stockouts, and inefficient warehouse usage.

On the other hand, data-driven planning requires an upfront investment in technology and high-quality data but delivers considerable long-term benefits. Studies show that data-driven forecasting can lower inventory costs by 15% and improve stock availability by 17%. This approach optimizes working capital, minimizes holding and devaluation costs, and enhances customer satisfaction by ensuring products are readily available. However, it does come with its own challenges, such as the need for staff training and regular updates to maintain the accuracy of automated systems.

"Data-driven decision-making is no longer a 'nice to have.' It's critical for maintaining a company's competitiveness, resilience and growth."

- Jeff Dehart, Managing Director, CBIZ Risk Advisory Services

The impact of these approaches on business performance is striking. For example, Hewlett-Packard's Mobile Computing Division saw inventory-driven costs drop from 18.7% of total revenue to just 3.8% after adopting a data-driven supply chain model between 1997 and 1999. This shift turned an unprofitable division into a profitable one. In contrast, Gap Inc. ended 2022 with $3.04 billion in unsold products - a 12% increase from the previous year - which forced heavy discounting and led to a five-percentage-point drop in merchandise margins.

Comparison Table: Pros and Cons

| Approach | Pros | Cons |

|---|---|---|

| Traditional Inventory Management | • Low initial technology cost • Suitable for small-scale operations |

• High long-term costs from obsolescence • Frequent stockouts • Inefficient use of warehouse space • Prone to human error |

| Data-Driven Planning | • Optimizes working capital • Cuts holding and devaluation costs • Enhances customer satisfaction • High accuracy with automation |

• Requires upfront investment • Depends on accurate, high-quality data • Needs staff training • Must be regularly updated to stay effective |

Implementing Data-Driven Planning with Tools like ForthClear

Switching from old-school inventory management to a data-driven system doesn’t have to be complicated. Tools like ForthClear make this shift smoother by automating the process of managing surplus inventory. By connecting directly to your e-commerce platform, ForthClear can spot dead stock early, helping free up capital that would otherwise be tied up. This kind of automation fits perfectly into a bigger data-driven strategy, offering businesses a smarter way to handle excess inventory while making onboarding a breeze.

Getting Started with ForthClear

For Shopify merchants, getting started is simple. Install the ForthClear app, and you can immediately start analyzing your inventory history. The app flags products that have been sitting idle for more than 60 days, cutting out the need for tedious spreadsheet reviews and giving you a heads-up on slow-moving stock before it becomes a financial burden.

If you’re not on Shopify, no problem. You can sign up directly on ForthClear’s website and upload your inventory using a CSV or Excel file. Their bulk upload tool even includes an auto-image search feature that finds product photos for you, saving time and effort. Once your inventory is in the system, you can set up tiered bulk pricing to encourage volume sales - for instance, offering a 20% discount for orders of 50 units or more.

After setup, the platform brings even more tools to the table to make surplus liquidation easier and more efficient.

Benefits of ForthClear for E-Commerce Businesses

ForthClear doesn’t just make surplus management easier - it helps reduce inventory waste while maximizing efficiency. The platform offers secure escrow payments powered by Stripe, ensuring that funds are only released once the buyer confirms delivery or after 14 days. It connects you to a network of verified buyers and even provides built-in tariff estimates for international shipping. This means you can expand your reach without worrying about the hassle of calculating cross-border costs manually.

Other standout features include a messaging system for direct negotiations with buyers and flexible volume-based pricing options. Plus, with no upfront listing fees and a low 5% platform fee charged only on successful sales, the financial risk of using ForthClear stays minimal.

"ForthClear has revolutionized how we handle excess inventory. The secure payment system and quality suppliers have made our sourcing process efficient." - Gordon Belch, Co-founder, vybey

Conclusion

Inventory waste often boils down to guesswork, but data-driven planning puts you firmly in control. Relying on intuition or outdated spreadsheets can trap capital in slow-moving stock and create blind spots in your supply chain. By contrast, data-driven methods leverage historical sales data, real-time insights, and automated problem detection to prevent these issues before they arise.

For businesses still clinging to manual processes, the advantage of switching is undeniable. Those who adopt data-driven tools experience immediate wins - freeing up working capital, improving cash flow, and reinvesting in growth rather than warehousing unsold inventory.

The path forward is clear: e-commerce businesses must embrace unified data systems and automated alerts. Tracking metrics like sell-through rates and days of inventory on hand is essential. Platforms like ForthClear make this transition seamless by automating surplus detection and connecting sellers with verified buyers, flagging products that sit unsold for over 60 days.

Abandoning outdated methods allows companies to strengthen their resilience and profitability. As Jeff Dehart, Managing Director of CBIZ Risk Advisory Services, aptly notes:

"Data-driven decision-making is no longer a 'nice to have.' It's critical for maintaining a company's competitiveness, resilience and growth".

The real question isn't whether to adopt these tools, but how quickly you can implement them to stay ahead of the curve.

FAQs

How does data-driven planning make inventory management more efficient?

Data-driven planning takes inventory management to the next level by leveraging insights from sales history, market trends, seasonal shifts, and even external challenges like supply chain disruptions. This method empowers businesses to predict demand with greater accuracy and make real-time adjustments to purchase orders. The result? Less surplus inventory and lower carrying costs.

With a clearer view of stock levels, businesses can avoid both stockouts and overstocking. By pinpointing which products are performing well, they can restock only what's necessary - helping to cut down on lost sales, reduce markdowns, and improve cash flow. Advanced tools, such as AI-powered forecasting, make the process even smoother by simplifying inventory tracking and enabling just-in-time replenishment. The outcome is a leaner, more efficient system that reduces waste and drives profitability.

How does reducing inventory waste benefit the environment?

Reducing inventory waste plays a key role in protecting the environment by cutting down on the volume of unused products that end up in landfills. This not only eases the burden on disposal sites but also helps lower methane emissions caused by decomposing waste. By using data-driven planning and demand forecasting, businesses can avoid overproduction, which means fewer resources are wasted on manufacturing, packaging, and transportation. The result? A noticeable reduction in their carbon footprint.

On top of that, adopting circular-economy practices - such as redistributing surplus goods, refurbishing items, or recycling - helps conserve natural resources and extends the life of products. These actions don’t just lower greenhouse gas emissions; they also reduce the need for new raw materials, helping to protect ecosystems. Combined, these strategies contribute to a more environmentally conscious supply chain and align with sustainability goals.

What are the best tools for managing surplus inventory efficiently?

Managing surplus inventory effectively begins with leveraging digital inventory platforms that offer real-time stock tracking and automated alerts for items that are slow-moving or nearing the end of their shelf life. These platforms often feature user-friendly dashboards, low-stock notifications, and analytics to help you monitor sales trends and turnover rates. By incorporating AI-powered forecasting, businesses can predict demand more accurately, using historical data and market trends to minimize the chances of overstocking.

For businesses operating in e-commerce, system integrations can pinpoint dead stock - typically items left unsold for 60 days or longer - and make it easier to list them on surplus marketplaces. Features like bulk-upload tools and automated notifications speed up the process, while secure platforms with escrow payment options and verified buyers ensure a smooth transaction. These solutions not only help turn excess inventory into revenue but also save storage space and make surplus inventory management more straightforward.