When buying in bulk, ensuring consistent quality is critical. ISO 9001-certified suppliers help reduce risks like defective inventory, supply chain disruptions, and financial losses. This global standard requires suppliers to follow strict quality management processes, leading to fewer defects, better efficiency, and stronger supplier reliability. Here's why ISO 9001 matters for bulk buyers:

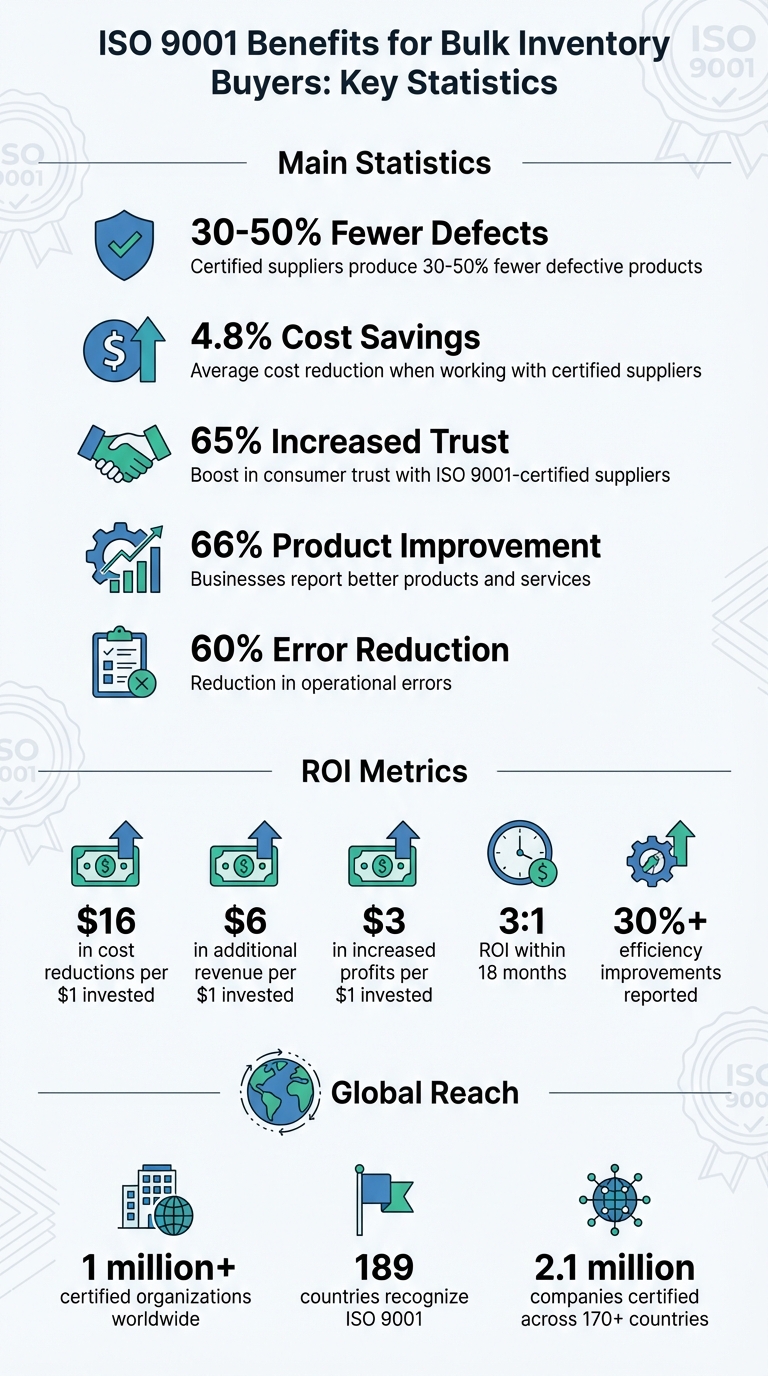

- Fewer Defects: Certified suppliers produce 30-50% fewer defective products.

- Cost Savings: Businesses save 4.8% on average by working with certified suppliers.

- Improved Trust: Certified suppliers boost customer trust by 65%.

- Risk Management: ISO 9001 promotes proactive strategies to prevent disruptions.

Platforms like ForthClear simplify bulk buying by connecting buyers with verified ISO 9001-certified suppliers, offering secure escrow payments, and providing tools for efficient inventory management. This approach ensures buyers get quality products, reduced waste, and better financial outcomes.

ISO 9001 Benefits for Bulk Inventory Buyers: Key Statistics

Common Challenges in Bulk Inventory Purchasing

Supplier Inconsistencies and Quality Risks

Working with unreliable suppliers can create a domino effect of operational problems. Issues like sudden shutdowns, poor management, or high employee turnover can disrupt communication and compromise product quality. When suppliers fail to meet expectations, it often leads to inconsistent quality, which can increase customer complaints and harm your brand's reputation. Supply chain disruptions, caused by fluctuations in supply and demand, can also impact delivery schedules and profit margins. Additionally, suppliers in developing regions may face heightened risks such as political instability, war, or climate-related disruptions, which can abruptly halt operations. These quality-related challenges often translate into financial and operational setbacks, as highlighted below.

Financial Implications of Defective Inventory

Defective inventory can take a serious toll on your finances. When purchasing in bulk, even a single quality issue can result in hundreds of unsellable products, leading to wasted capital. Take the case of Blue Bell in April 2015: the company had to halt production and recall products across 23 states after a listeria outbreak linked to 10 infections and three deaths. Investigators found that listeria had been detected as early as 2013, but inadequate quality controls led to a four-month shutdown, costing the company significant market share during the busy summer season.

"If something goes amiss and hundreds of defective products are created before anyone notices, then the company has wasted money on products that won't be able to be sold to customers." - Creative Safety Supply

Inconsistent quality doesn't just hurt your bottom line through unsellable goods. It also increases return rates, which add to administrative and logistical costs while cutting into revenue. Beyond these immediate losses, handling defective stock requires extra labor and can tarnish your reputation, potentially driving away future customers. These financial burdens only add to the inefficiencies already present in supply chain operations.

Inventory Waste and Supply Chain Inefficiencies

Defective inventory wastes more than just money - it also drains labor, materials, and time, especially when items are deemed unsellable. Quality inspections often act as "lag indicators", meaning defects are only discovered after production is complete and costs have been incurred. In large-scale operations, a single error in the production process can lead to hundreds or even thousands of defective products before the issue is caught.

"Waste results from poor quality and inefficiency. Inefficiency results from variation and inconsistent processes. Reduce variation, improve consistency, and you'll have less waste…and more money." - Bizmanualz

Such failures ripple through the supply chain, creating additional inefficiencies. These include longer wait times, reduced productivity, and the need for extra buffer inventory to mitigate quality issues. According to Six Sigma standards, any manufacturing process with more than 3.4 defects per million products is considered inefficient - a clear sign of the high costs tied to poor quality control. Process inconsistencies lead to unpredictable outcomes, requiring more oversight and generating even greater waste.

ISO 9001 Clause 8.4.2 Explained - Purchasing - Part 2

How ISO 9001 Certification Addresses Bulk Buying Challenges

ISO 9001 sets the groundwork for dependable quality management systems, tackling many challenges that arise with bulk buying. Rather than relying on last-minute quality checks or fixing issues after they occur, certified suppliers follow structured, documented procedures to ensure consistency. With nearly one million ISO 9001 certificates issued globally, this standard has become a trusted benchmark for supplier reliability. Here’s a closer look at how ISO 9001 ensures steady supplier performance.

Standardized Processes for Supplier Reliability

ISO 9001 requires suppliers to implement repeatable processes that guarantee consistent product quality and delivery. It emphasizes evaluating external supplier performance as part of an organization’s overall operations. Leadership plays a key role, as the standard mandates that senior management allocate the necessary resources to maintain an effective Quality Management System (QMS). According to NSF:

"ISO 9001 is designed to help organizations implement repeatable processes so they can produce or deliver quality products or services – and customer satisfaction – consistently."

Certification involves annual audits and a comprehensive recertification process every three years. Buyers should confirm that a supplier's ISO 9001 certification comes from an accredited, independent third-party body.

Quality Assurance and Defect Reduction

ISO 9001 enforces strict quality control measures to minimize defects in bulk inventory. For example, Clause 8.4.1 requires suppliers to meet specific requirements, while Clause 8.6 ensures that products are validated against acceptance criteria before entering inventory. These steps ensure that any damage, quality issues, or deviations from order specifications are caught early.

Additionally, Clause 8.7 focuses on identifying and separating nonconforming goods, while Clauses 7.1.5 and 10.2 emphasize the importance of calibrated monitoring tools and thorough root-cause investigations for corrective actions. Together, these measures have contributed to the certification of over 2.1 million companies across more than 170 countries.

Risk-Based Thinking and Supply Chain Resilience

ISO 9001 doesn’t stop at quality control - it also promotes proactive risk management to enhance supply chain resilience. By requiring organizations to analyze their "context" - including suppliers and other stakeholders - it helps identify potential risks that could disrupt inventory management. This forward-thinking approach allows buyers to address supply chain vulnerabilities before they escalate. As NSF explains:

"As most organizations work in a complex ecosystem involving a supply chain, customers, and other stakeholders, they are required to analyze the organization's context relative to its QMS."

With mandatory audits in the first two years and a full recertification in the third, ISO 9001 ensures that risk management strategies stay up-to-date. For bulk inventory buyers, including ISO 9001 certification as a requirement in Requests for Proposals (RFPs) can help secure suppliers with proven, validated systems for managing quality and risk.

sbb-itb-bc600a0

Key Benefits of ISO 9001 for Bulk Inventory Buyers

Sourcing from ISO 9001-certified suppliers brings measurable advantages that can boost your bottom line and streamline operations. According to statistics, businesses experience a 65% increase in consumer trust and a 66% improvement in products and services when working with ISO 9001-certified suppliers. These benefits translate into better quality, greater efficiency, and stronger market confidence, as outlined below.

Improved Product Quality and Buyer Confidence

Certified suppliers prioritize reliability, delivering 30% to 50% fewer defects compared to non-certified vendors. This improvement stems from the standardized processes and continuous improvement practices required by ISO 9001. The certification ensures decisions are based on data, not guesswork, leading to a 60% reduction in operational errors. For bulk buyers, this means peace of mind - no more worrying about shipments arriving with quality issues that could disrupt your business.

Increased Efficiency and Cost Savings

Dealing with uncertified suppliers often leads to inefficiencies, but ISO 9001-certified suppliers help eliminate these problems, resulting in significant cost savings. On average, certified suppliers reduce costs by 4.8%. For every dollar invested in a Quality Management System, companies report $16 in cost reductions, $6 in additional revenue, and $3 in increased profits. These savings come from fewer production errors, less waste, and better inventory management. For instance, one job shop identified a 60% redo rate in their processes before ISO 9001 corrective actions resolved the issue. For bulk buyers, these efficiency gains translate into faster order fulfillment, reduced storage costs, and less capital tied up in defective or slow-moving inventory.

Access to Verified Suppliers and Market Trust

ISO 9001 certification acts as a global quality benchmark, recognized in 189 countries and by over 1 million certified organizations. It also ensures a structured approach to resolving complaints, offering a clear path to address any issues with bulk orders. Companies working with certified suppliers typically see a 3:1 return on investment within 18 months, with many reporting efficiency improvements of 30% or more. This certification not only strengthens supplier relationships but also reduces procurement risks and gives buyers a competitive edge in markets where quality and reliability are critical.

Using ISO 9001 with ForthClear for Smarter Inventory Buying

ForthClear brings ISO 9001's quality management principles to life with practical, user-friendly tools. It tackles essential aspects like supplier verification, asset protection, risk reduction, and clear communication, making surplus inventory transactions more efficient and reliable.

Verified Suppliers and Escrow Protection

ISO 9001's Clause 8.4.1 emphasizes the importance of evaluating and selecting suppliers based on quality standards. ForthClear ensures this by thoroughly vetting all suppliers, creating a trusted network of verified partners. This process aligns with ISO 9001's focus on managing external providers throughout the supplier relationship lifecycle.

To further enhance security, ForthClear uses a secure Stripe escrow system. This feature holds funds until the buyer confirms delivery or automatically releases them after 14 days, significantly reducing the risk of fraud.

Auto-Detect and Optimize Dead Stock Acquisition

ForthClear's Auto-Detect feature is a game-changer for Shopify store owners. It automatically flags products that have remained unsold for over 60 days, marking them as surplus inventory. This aligns with ISO 9001's emphasis on proactive, risk-based strategies, helping sellers quickly move aged stock and avoid cash flow problems.

For buyers, this means access to surplus inventory at bulk pricing. ForthClear also supports tiered pricing strategies, such as "Buy 50+ and get 20% off", encouraging larger orders without sacrificing quality. These tools are part of ForthClear's broader commitment to streamlining surplus inventory management while maintaining high standards.

Real-Time Communication and Order Tracking

Transparency is a cornerstone of ISO 9001, and ForthClear delivers with its real-time messaging system. Buyers and sellers can negotiate directly, creating a documented communication trail that supports quality audits and highlights any product issues.

Additionally, ForthClear's order tracking tools provide complete visibility from purchase to delivery, eliminating the confusion often caused by manual tracking. This transparency empowers users to make informed, data-driven decisions.

"Effective decisions are based on the analysis and interpretation of information and data." - ISO 9000 Quality Management Principle

With no listing fees and a modest 5% platform fee on completed sales, ForthClear offers a budget-friendly solution for buyers looking to build supplier relationships that align with ISO 9001's principles.

Conclusion

Working with ISO 9001-certified suppliers lays the groundwork for trust, efficiency, and long-term savings. As the global standard for quality management, ISO 9001 ensures suppliers adhere to standardized processes that minimize defects, cut waste, and maintain consistent product quality - even for large-scale orders.

Statistics back this up: 66% of businesses report better products and services, while 60% see fewer operational errors. This translates to reduced returns and lower rework costs. With its emphasis on risk-based thinking, ISO 9001 enables suppliers to spot and address potential issues before they escalate.

Platforms like ForthClear take these benefits a step further. By combining ISO 9001's structured approach with ForthClear's tools, buyers gain a seamless experience. Verified suppliers, secure escrow payments, and real-time tracking foster transparency and efficiency. Plus, features like ForthClear's Auto-Detect make it easy to find surplus inventory at competitive bulk prices, while built-in communication tools ensure every transaction is well-documented and traceable.

"ISO 9001 helps organizations ensure their customers consistently receive high quality products and services." - ASQ

FAQs

How does ISO 9001 certification ensure reliable suppliers for bulk inventory buyers?

ISO 9001 is a well-known standard for quality management, ensuring that suppliers establish and improve processes to meet customer demands and comply with regulatory rules. Suppliers with this certification follow rigorous procedures to consistently deliver products that align with agreed-upon standards. For bulk buyers, this provides peace of mind about the reliability and quality of their orders.

This certification also pushes suppliers to identify potential risks, set up preventive measures, and track key performance indicators like on-time delivery rates and defect levels. Independent audits confirm these processes are effective, which means buyers don’t have to invest as much time and effort in their own evaluations. For those purchasing in bulk, this translates to fewer disruptions, lower costs from defective products, and a smoother supply chain.

On platforms like ForthClear, choosing ISO 9001-certified sellers makes the vetting process easier. It guarantees consistent product quality and dependable order fulfillment, helping businesses maintain steady inventory flow and improve profitability in large-scale operations.

What financial advantages do bulk buyers gain from choosing ISO 9001-certified suppliers?

Working with ISO 9001-certified suppliers can help bulk buyers cut costs and boost profitability. These suppliers focus on efficient operations, which means less waste, smoother processes, and reduced inventory costs.

On top of that, ISO 9001-certified suppliers excel in managing risks, ensuring consistent product quality and fewer disruptions. This dependability translates to fewer product returns, stronger supplier partnerships, and lasting financial advantages for buyers.

How does ISO 9001 certification help bulk inventory buyers reduce supply chain risks?

ISO 9001 certification plays a crucial role in helping bulk inventory buyers mitigate supply chain risks. By requiring suppliers to adhere to strict quality standards and maintain consistent process control, it ensures that only dependable suppliers make the cut. This significantly lowers the risk of defective or non-compliant products finding their way into your inventory.

The certification also emphasizes proactive risk management. It encourages businesses to anticipate potential disruptions - like delayed shipments, quality problems, or regulatory shifts - and take preventive actions. These might include developing alternative sourcing plans or ramping up inspection protocols. With its focus on continuous improvement and data-backed decisions, ISO 9001 not only protects product quality but also strengthens overall business operations while reducing the financial fallout from supply chain hiccups.