Businesses are turning surplus inventory into opportunities by collaborating across industries. This approach, known as cross-industry surplus collaboration or industrial symbiosis, connects unused materials from one sector with the needs of another, reducing waste and unlocking new revenue streams.

Key takeaways:

- What it is: Companies share surplus resources (e.g., materials, inventory) across industries to repurpose them.

- Why it matters: Reduces waste, lowers greenhouse gas emissions, cuts costs, and creates new income opportunities.

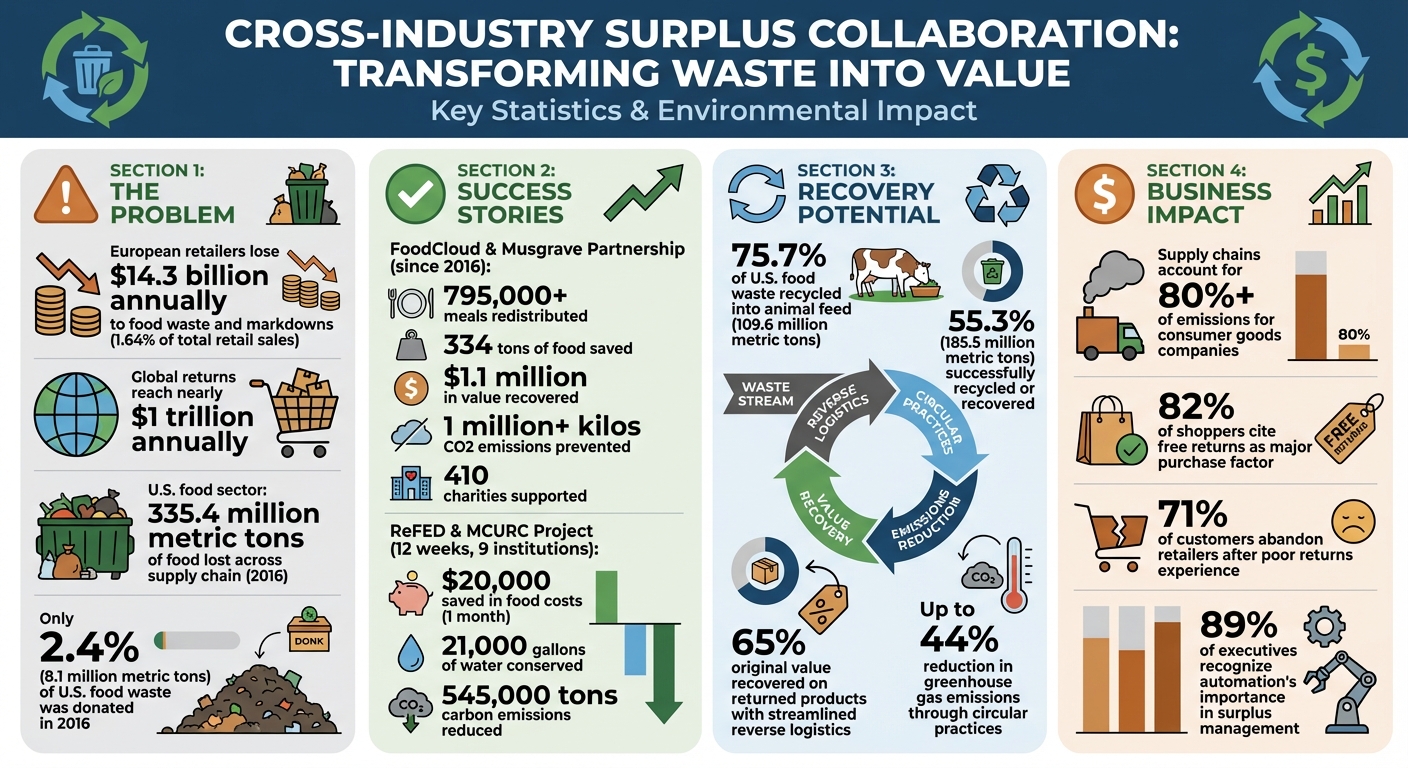

- Examples: FoodCloud redistributed over 795,000 meals, saving $1.1M and preventing 1M kilos of CO2 emissions.

- Tools like ForthClear: Platforms simplify surplus management by connecting sellers with buyers, automating processes, and reducing landfill waste.

This strategy is transforming inventory management by turning surplus into a circular, resource-sharing system that benefits both businesses and the planet.

Cross-Industry Surplus Collaboration Impact: Key Statistics and Benefits

Key Findings from Recent Studies

Food Sector: A Model for Collaboration

The food industry sets a strong example of how partnerships can effectively manage surplus. In 2016, about 335.4 million metric tons of food were lost across the U.S. supply chain, but manufacturers managed to recycle 75.7% of that (109.6 million metric tons) into animal feed.

One standout initiative is the partnership between Musgrave MarketPlace and FoodCloud. Since joining forces in 2016, they’ve redistributed over 795,000 meals (334 tons of food, valued at roughly $1.1 million) to 410 charities. By late 2025, this effort is expected to prevent more than 1 million kilos of CO2-equivalent emissions. Aoibheann O'Brien, Partnerships Director at FoodCloud, highlighted the impact:

"Musgrave MarketPlace is an excellent example of an organisation that has expanded its operation with us over the years... To reach more than 795,000 meals redistributed since then is an incredible milestone".

Another example comes from Tesco and Branston, who turned off-standard produce into ready-made meals and frozen products. This approach not only prevented waste from being diverted to animal feed or disposal but also helped improve profitability.

Interestingly, this collaborative approach is not limited to food. Similar trends are emerging in other industries as well.

Pharmaceutical Innovations in Surplus Donations

The pharmaceutical sector is following the food industry's lead by finding ways to repurpose surplus for public health needs. Initiatives in this space focus on redirecting unused products from manufacturers to underserved areas. While quantitative data is limited, these efforts highlight the growing role of collaboration in addressing health-related challenges.

Measurable Benefits Across Industries

The benefits of surplus collaboration span financial and environmental gains across various sectors. For instance, in October 2024, ReFED teamed up with the Menus of Change University Research Collaborative (MCURC) for a 12-week project involving nine institutions. Their goal? To repurpose overproduced food into new menu items. Within just one month, the project saved nearly $20,000 in food costs, 21,000 gallons of water, and 545,000 tons of carbon emissions.

The economic stakes are high. European retailers lose over $14.3 billion annually to food waste and markdowns, equivalent to 1.64% of total retail sales. In the U.S., only 2.4% (8.1 million metric tons) of food loss and waste was donated in 2016, despite donation being the most effective recovery method. This gap presents a major opportunity for businesses to reclaim value while advancing sustainability efforts.

On a brighter note, 55.3% (185.5 million metric tons) of U.S. food waste is successfully recycled or recovered, primarily for animal feed and industrial uses. However, the consumption stage - households and food services - lags behind, with 88.7% of waste ending up in landfills, incineration, or wastewater treatment. These findings underline the potential for even greater financial and environmental gains through cross-industry collaboration.

Opportunities for E-Commerce Businesses

Turning Overstock into Cash Flow

For e-commerce businesses, unsold inventory can feel like a double-edged sword - it ties up capital and eats up valuable storage space. But there’s a solution: transforming surplus goods into cash through cross-industry collaborations. Companies with streamlined reverse logistics systems can recover as much as 65% of the original value on returned products. Mary Cho, Director of Client Solutions at Liquidity Services, highlights the benefits:

"Direct-to-consumer marketplaces provide great engagement with the end buyers... the closer we can get to the end buyers, the higher the revenue recovery".

B2B marketplaces also play a crucial role. These platforms connect merchants with verified wholesale buyers who purchase in bulk, often providing offers within 48 hours - provided sellers include detailed inventory manifests with SKU numbers, UPC codes, item conditions, and quantities. This faster sales cycle is particularly effective for moving bulk or lower-value items.

Clearing out excess inventory does more than just free up space. It improves cash flow, reduces operational strain, and opens up opportunities for innovative reuse. For instance, some businesses are exploring industrial symbiosis - selling overstock as raw materials for manufacturers in other industries. One example? Used packaging materials being repurposed by bag manufacturers. This approach not only recovers capital but also lays the groundwork for more sustainable operations.

Weaving Sustainability into Everyday Practices

Beyond financial advantages, embracing sustainable surplus practices can enhance both a business’s reputation and its environmental impact. Today’s consumers are increasingly conscious of how companies handle waste, and participating in surplus programs aligns with the rising demand for eco-friendly commerce. In fact, adopting circular practices can slash greenhouse gas emissions by up to 44%, giving businesses measurable environmental achievements to share with their customers.

But it’s not just about optics. As McKinsey & Company notes:

"Reimagining the traditional linear flow of supply chains to support circularity could be a growing source of value for companies, consumers, and the planet".

Shifting toward circular business models isn’t just a “nice-to-have” anymore - it’s becoming a competitive edge. Consumers are increasingly drawn to companies that embrace circularity.

Another impactful strategy? Partnering with nonprofits. Troy Campbell, Director of Reverse Logistics Centers at The Home Depot, explains:

"When one of our donation partners faces a shortage, we determine if there is product we can provide - often items that would otherwise be sold through our liquidation channels".

This approach not only strengthens community ties but also supports ESG goals. For e-commerce businesses, effective surplus management is key, especially when 82% of shoppers cite free returns as a major factor in their purchasing decisions. However, a poor returns experience can drive 71% of customers away from a retailer for good. By managing surplus thoughtfully, businesses can protect customer trust while building more sustainable and efficient operations.

sbb-itb-bc600a0

ForthClear: A Platform for Cross-Industry Collaboration

How ForthClear Simplifies Surplus Inventory Sales

ForthClear takes the hassle out of managing surplus inventory by identifying dead stock - items that remain unsold for 60 days or more - and connecting sellers with verified bulk buyers. Through its Shopify App integration, the platform scans inventory history, flags slow-moving products, and enables users to list these items with just a few clicks. No need for tedious spreadsheets or guesswork.

To ensure secure transactions, ForthClear uses Stripe escrow payments, holding funds until buyers confirm delivery or automatically releasing them after 14 days if no disputes arise. For merchants handling large volumes, the bulk upload tool includes an auto-image search feature that quickly finds product photos, saving significant time and speeding up the listing process.

This efficient system not only helps sellers recover capital quickly but also offers buyers access to high-quality surplus inventory at competitive prices. A 2023 survey found that 89% of executives acknowledged the importance of automation in simplifying these processes. Beyond improving sales efficiency, ForthClear’s tools play a pivotal role in reducing waste by keeping surplus items in circulation.

ForthClear's Role in Reducing Waste

ForthClear goes beyond sales automation by promoting industrial collaboration, redirecting surplus inventory from waste streams to productive use. By connecting businesses across industries, the platform helps prevent products from ending up in landfills, ensuring they remain valuable. This approach is especially significant in an industry where supply chains account for over 80% of emissions for typical consumer goods companies.

The platform’s real-time messaging system and network of verified buyers eliminate communication bottlenecks that often delay surplus redistribution. Sellers can negotiate directly with buyers, share detailed inventory manifests, and close deals more efficiently. With global returns reaching nearly $1 trillion annually, effective surplus management is crucial for transforming potential waste into recoverable value. ForthClear makes this process straightforward for e-commerce businesses of any size, offering a practical solution that balances profitability with sustainability - without the complications of traditional liquidation methods.

Conclusion: The Future of Surplus Collaboration

Cross-industry surplus collaboration is reshaping inventory management, turning it from a one-way process into a circular, resource-sharing system. By cutting back on the use of new raw materials, businesses not only reduce their environmental footprint but also protect themselves from the unpredictability of price swings and geopolitical disruptions.

Research has consistently shown the immediate environmental and financial upsides of circular practices. These aren't far-off predictions - they're opportunities that companies can seize right now by rethinking outdated inventory strategies.

"Circular supply chains are enabled by close collaborative practices with suppliers, product designers and regulators, as well with actors within and beyond their immediate industrial boundaries."

- Anne Ratsimandresy, Sustainability Researcher

Digital platforms are at the heart of this transformation. They close the information gap between industries, make cross-sector partnerships possible, and handle the logistical challenges of redistributing surplus. With tools like automated inventory tracking, secure transactions, and networks of verified buyers, these platforms make it easier than ever for businesses - large or small - to turn surplus stock into revenue.

Looking ahead, companies that embrace surplus collaboration will position themselves as leaders. As regulations tighten and consumers increasingly demand sustainable practices, those who adapt early will enjoy a competitive edge over those clinging to traditional, linear models. The infrastructure is ready, the benefits are clear - what’s left is execution. By viewing surplus as a resource rather than waste, businesses can achieve both environmental progress and a stronger market position.

FAQs

How does collaboration across industries help reduce surplus and benefit the environment?

Collaboration across industries enables companies to exchange surplus inventory - like electronics, clothing, or raw materials - so these items can be reused, refurbished, or repurposed instead of being thrown away. This practice helps extend the lifespan of products and materials, cutting down on waste and conserving resources.

By redirecting surplus stock from landfills, these initiatives play a big role in lowering greenhouse gas emissions and reducing the demand for new raw materials. This not only saves energy but also limits environmental damage. Plus, large-scale collaborative systems that manage excess inventory make processes like recycling and remanufacturing more efficient, further lessening the environmental burden.

These partnerships support a circular economy, where resources are used more responsibly. The results? Healthier ecosystems, less pollution, and a meaningful step toward addressing climate change - all while delivering economic advantages for the businesses involved.

How do digital platforms support cross-industry surplus inventory collaboration?

Digital platforms have become a game changer for managing surplus inventory, connecting manufacturers, retailers, and distributors in real time. They make it possible for businesses to match surplus stock with others who need it, cutting down on over-ordering and trimming warehousing expenses. Platforms like ForthClear simplify the process by offering features such as secure escrow payments, verified supplier credentials, bulk pricing options, and order tracking. This setup reduces risks and smooths out the buying and selling of surplus goods across various categories, including electronics, apparel, and home goods.

But these platforms do more than just facilitate transactions. They also provide advanced tools designed to improve collaboration and efficiency. Using data-driven technologies, businesses can engage in joint forecasting, better inventory management, and smarter production planning. These tools help align operations, minimize waste, and transform surplus inventory from a liability into a strategic asset. In doing so, companies not only save money but also take steps toward supporting a more sustainable and circular economy.

What are the best strategies for e-commerce businesses to manage surplus inventory effectively?

Managing surplus inventory in e-commerce requires a shift in perspective - viewing excess stock not as a burden but as an opportunity. Common culprits like overproduction, inaccurate demand predictions, and fast-moving product cycles often leave businesses with unsold goods, tying up capital and increasing waste. However, businesses can turn this challenge around by embracing circular economy practices. Approaches such as refurbishing, redistributing, or reselling items not only cut down on disposal costs but also align with growing consumer interest in sustainability and ensure compliance with U.S. regulations.

Using data-driven tools like predictive analytics and machine learning can make a significant difference. These technologies help fine-tune inventory management, improve demand forecasting, and reduce the chances of overstocking. On top of that, reverse logistics systems simplify the process of handling returns and unsold goods, making it easier to prepare them for resale or redistribution. Platforms like ForthClear offer secure digital marketplaces where businesses can offload surplus inventory efficiently while maintaining control and transparency.

By adopting these strategies, e-commerce companies can tackle surplus inventory head-on, freeing up cash flow, building a more sustainable supply chain, and enhancing their competitive position. This is especially critical in a market where U.S. retailers collectively hold unsold goods worth hundreds of billions of dollars.